The rise of additive manufacturing is changing the face of CNC precision engineering. Additive manufacturing has become more affordable, especially for smaller businesses that can’t afford expensive machinery.

It’s also easier to learn and use than ever before thanks to advancements in software and hardware technologies.

But what’s really driving this growth?

Profitability is the driving force behind many companies’ adoption of additive manufacturing (AM). With AM, companies no longer have to invest heavily in capital equipment, which means they can save money on up-front costs and focus on other areas where they can grow their business.

The rise of additive manufacturing

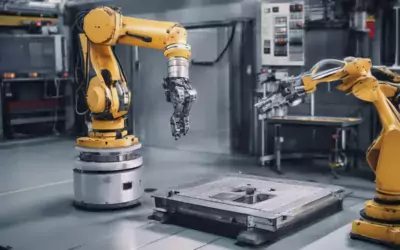

Additive manufacturing (AM), also known as 3D printing, is the use of a digital design to create a three-dimensional object.

The process involves additive processes, where successive layers are added to the object. This differs from traditional manufacturing methods that involve cutting away material until you achieve your desired shape.

Profitability is the driving force

The driving force behind the growth of CNC precision engineering is profitability. New materials, new production equipment and processes are enabling new or recently developed applications to be created. These developments are being fueled by rising demand for products that can be achieved with higher levels of accuracy and quality than in the past.

The impact on you as a manufacturer can be significant: when you choose to invest in new equipment or processes, it will pay off within just a few months!

And as we’ve seen from other industries like robotics, 3D printing and additive manufacturing (AM), if you don’t move fast enough to take advantage of these opportunities early on then someone else will beat you to it – possibly one of your competitors who already have their foot in the door.

The booming aviation industry

The booming aviation industry is a major driver of the demand for CNC precision engineering.

As you probably already know, aircraft manufacturers need to make parts that are precise and reliable. The aviation industry has grown substantially in recent years, with more and more people taking to the skies. And as they’ve become more popular, manufacturers have also been forced to compete against one another in order to stand out from their competitors. This means there’s more pressure than ever on each manufacturer’s bottom line—and this has led many companies in this field looking for ways that they can cut costs without sacrificing quality or performance.

Additive manufacturing (or 3D printing) offers a promising solution: it allows engineers to create complex parts at low cost while still providing high levels of accuracy and reliability needed by today’s aerospace companies. As these technologies continue improving over time—and as new applications open up in other industries like healthcare—we expect demand for CNC precision engineering services will continue growing exponentially over time!

Conclusion

The future of additive manufacturing is bright and getting brighter. It’s time to take advantage of this new technology and get it on the ground floor.