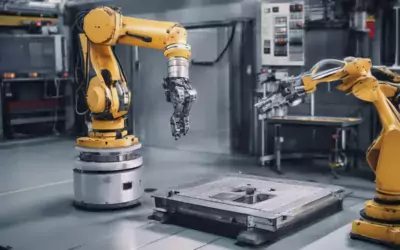

Automation’s ongoing surge in popularity has led to an increased demand for various essential components such as bar feeders, pallet changers, and gantry robots, fostering a significant drive towards efficiency and productivity enhancement in diverse manufacturing setups, from large industrial plants to compact workshops.

The growing accessibility and affordability of these technologies have played a pivotal role in reshaping the manufacturing landscape, particularly with the progressive reduction in the prices of 5-axis machines. As a result, businesses of all sizes can now leverage advanced equipment for streamlined operations, consolidating various machining processes into a single, powerful unit.

The Evolution of CNC Machine Services

Pioneering the Digital Shift in Manufacturing The roots of contemporary CNC (Computer Numerical Control) machines can be traced back to the innovative concepts of numerical controls for machine tools (NC) introduced by the visionary John T. Parsons in the 1940s. Originally developed to address the complex requirements of aircraft part manufacturing, these numerical controls evolved substantially over the decades.

The 1970s marked a crucial turning point for the industry, witnessing the widespread integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), alongside the exponential growth in the adoption of CNC machines across various sectors. The ensuing years witnessed a profound revolution in manufacturing automation, transforming the operational landscape of industries globally.

The Contemporary Realm of CNC Manufacturing

Enabling Seamless Connectivity and Advanced Precision In the contemporary scenario, CNC machine tools embody a seamless blend of intricate design and cutting-edge technology, heralding a paradigm shift in the realm of digital manufacturing. Equipped with advanced capabilities, these machines are meticulously integrated with sophisticated Manufacturing Resource Planning (MRP) systems and precision measuring probes, empowering manufacturers to achieve unprecedented levels of accuracy and operational efficiency. However, the growing integration and interconnectivity of these systems demand meticulous attention to detail, requiring robust measures to prevent potential breakdowns that might lead to costly disruptions in the production processes.

Meeting the Growing Demand for 5-Axis CNC Machines

Empowering Precision and Diversification in Manufacturing The escalating demand for 5-axis CNC machines signifies a pivotal shift in the industry’s focus towards enhanced precision and operational diversification. With the ability to manipulate workpieces or cutting tools along five different axes simultaneously, these machines have emerged as indispensable tools for machining complex components across an array of industries, including aerospace, automotive, and advanced engineering. Driven by the pressing need for expedited installation times, extended tool lifespans, and optimal cutting positions, manufacturers are increasingly investing in advanced CNC technology to meet the ever-evolving demands of modern production environments.

Anticipating the CNC Machines of Tomorrow

Integrating Industry 4.0 for Unprecedented Manufacturing Capabilities The convergence of CNC technology and Industry 4.0 represents a pivotal milestone in the realm of manufacturing, heralding a new era of intelligent and autonomous production systems. Leveraging the power of the Industrial Internet of Things (IIoT), the amalgamation of CNC machines with smart sensors and interconnected systems enables real-time monitoring, diagnostics, and adaptive responses, facilitating seamless self-correction and error mitigation during the manufacturing processes. While this transformation is expected to reshape the workforce dynamics, it also offers a unique opportunity to upskill and train existing personnel, empowering them to navigate and manage the intricacies of these advanced systems.

The Collaborative Future of CNC Machining

Paving the Way for Innovations and Synchronization in Manufacturing In critical industries such as medical device manufacturing, the fusion of CNC and CAM technologies has emerged as a cornerstone of quality assurance and precision engineering. The seamless integration of CNC and CAM solutions enables manufacturers to produce flawless components with unparalleled accuracy, catering to the stringent quality standards and regulatory requirements governing the medical device sector. Moreover, the ongoing evolution of CNC machining is poised to revolutionize the operational efficiency and productivity of diverse manufacturing setups, setting the stage for synchronized operations and interconnected manufacturing systems that drive the seamless transition from conceptual prototypes to large-scale, precision-driven production units.

Looking ahead

The future of CNC machining promises a dynamic trajectory of perpetual advancements and innovations, reshaping the operational dynamics and manufacturing capabilities across a multitude of industries, ranging from aerospace and automotive engineering to advanced medical devices and electronics.

With a relentless focus on precision engineering and operational excellence, the CNC machining sector is poised to become the cornerstone of a new era of technologically empowered manufacturing ecosystems, revolutionizing the global industrial landscape.