CNC machines are essential for smart factories because they allow manufacturers to meet their customers’ increasing expectations. Customers want faster delivery times, higher quality products and better service. To meet these demands, manufacturers must constantly improve their equipment and processes so that they can stay competitive in the marketplace.

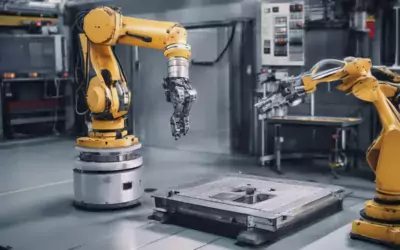

CNC machines enable this process by allowing companies to automate repetitive tasks that would otherwise require manual labor from employees who might not be able to keep up with increased production demands. They also enable companies to scale up production quickly when needed without having to hire additional staff members or invest in expensive new buildings or machinery (which may still not be enough).

What Software Can Do For CNC Machines

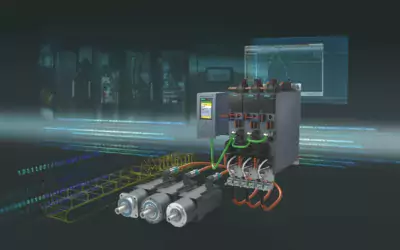

The software that connects CNC machines is the key to unlocking their potential. This software can allow you to connect different machines, introduce new features and make complex geometries possible.

- Retrofitting and Replacing Machines

- Laser measurement

- Network connectivity, including Ethernet and wireless systems

- Electrical controls (e.g., PLCs)

- Operating systems, such as Linux or Windows 10 IoT Core; these can be used to control robots or other devices that are connected to CNC machines through the cloud.

Functionality Is Always Improving

The future of CNC machines is a bright one. As the technology advances, we will see an increase in their speed and precision. In addition, they will become easier to monitor and maintain as well as more affordable for small businesses.

Investing in the Future

If you’re looking to invest in the future of manufacturing, it’s important to understand how CNC machines can help you compete on range and precision. As a result of this increased accuracy, companies will be able to specialize and reduce stock, build-to-order rather than relying on batch production, and focus on high value added processes.

If your company wants to take advantage of these benefits but doesn’t have the resources or expertise required to implement them yourself, consider partnering with someone who does–like us! We provide end-to-end solutions for smart factories: from building custom CNC machines that are designed specifically for your needs (and budget), through training staff how best utilize them within their workflow process

Complete Business Transformation

The future of CNC machines in smart factories is one of complete business transformation.

The most obvious benefit is that you will be able to eliminate waste, which is good for the environment and your customers. It’s also good for your bottom line: waste costs money!

Options for Upgrading CNC Machines

There are two options for upgrading your CNC machines:

You can either replace or retrofit them. If you want to replace your machine, then you will need to buy a new one and dispose of the old one. You should also consider whether it is cost effective for you to do so. On the other hand, if you want to upgrade by adding software and accessories that will improve its performance or make it easier for users (such as yourself) then this may be more worthwhile than buying an entirely new machine altogether.

The other option is simply replacing parts within an existing system rather than buying an entirely new one altogether; this can be done either manually or automatically depending on what kind of part needs replacing and how much effort has gone into designing it beforehand.

What to Consider When Upgrading

When you’re planning to upgrade your CNC machines, there are a few things to consider. First, what are the business advantages? Second, how will it affect the customer experience and time-to-market for your products?

If you’re looking for a new supplier or want to switch from manual programming to CAM software that automates part creation and machining processes, then these questions may help:

What kind of software does this machine use? Is it compatible with other systems in place at my company (e.g., ERP)? Does it have any unique features I can take advantage of as part of an overall smart factory strategy?

How long has this manufacturer been around–and what kind of reputation do they have among their customers’ peers? Are they likely candidates for future upgrades as technologies evolve over time (e.g., 5G connectivity)?