Ordering replacements bearings can be a mind boggling operation. All those letters and numbers, prefix’s and suffixes, you’d be forgiven for just passing the job of ordering the bearings on to someone else, or just pay out the nose for it by going back to the machine builder. But it doesn’t need to be quite so complicated, not if you know the standard coding for bearings.

In this post we’ll quickly go through the standard coding for all bearings.

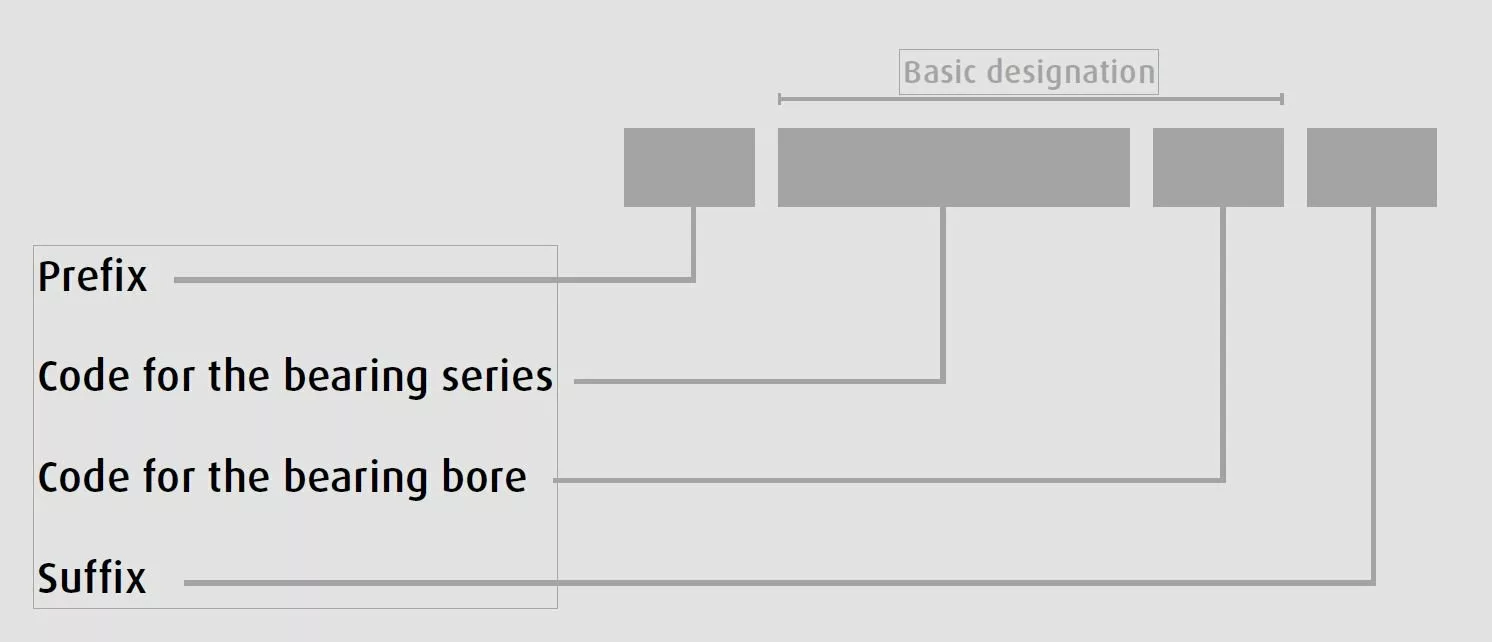

Order codes for bearings consist of a combination of letters and numbers, representing vital information about the type, size, and structure of the bearing. This alphanumeric combination helps in distinguishing between the basic designation and any prefixes or suffixes associated with the order code.

The basic designation within the order code signifies the bearing type and the bore size. These designations adhere to the German DIN 623 standard and the applicable ISO standard. While most bearing types utilize numerical designations, some may incorporate alphanumeric characters.

Prefixes and suffixes in the order code indicate specific modifications, such as deviations from the standard internal clearance or accuracy. However, it is important to note that the use of prefixes and suffixes is only partially standardized across the industry. Suffixes, in particular, tend to vary significantly as different bearing manufacturers employ their own unique codes to represent distinct modifications.

How the order codes for bearings are made up

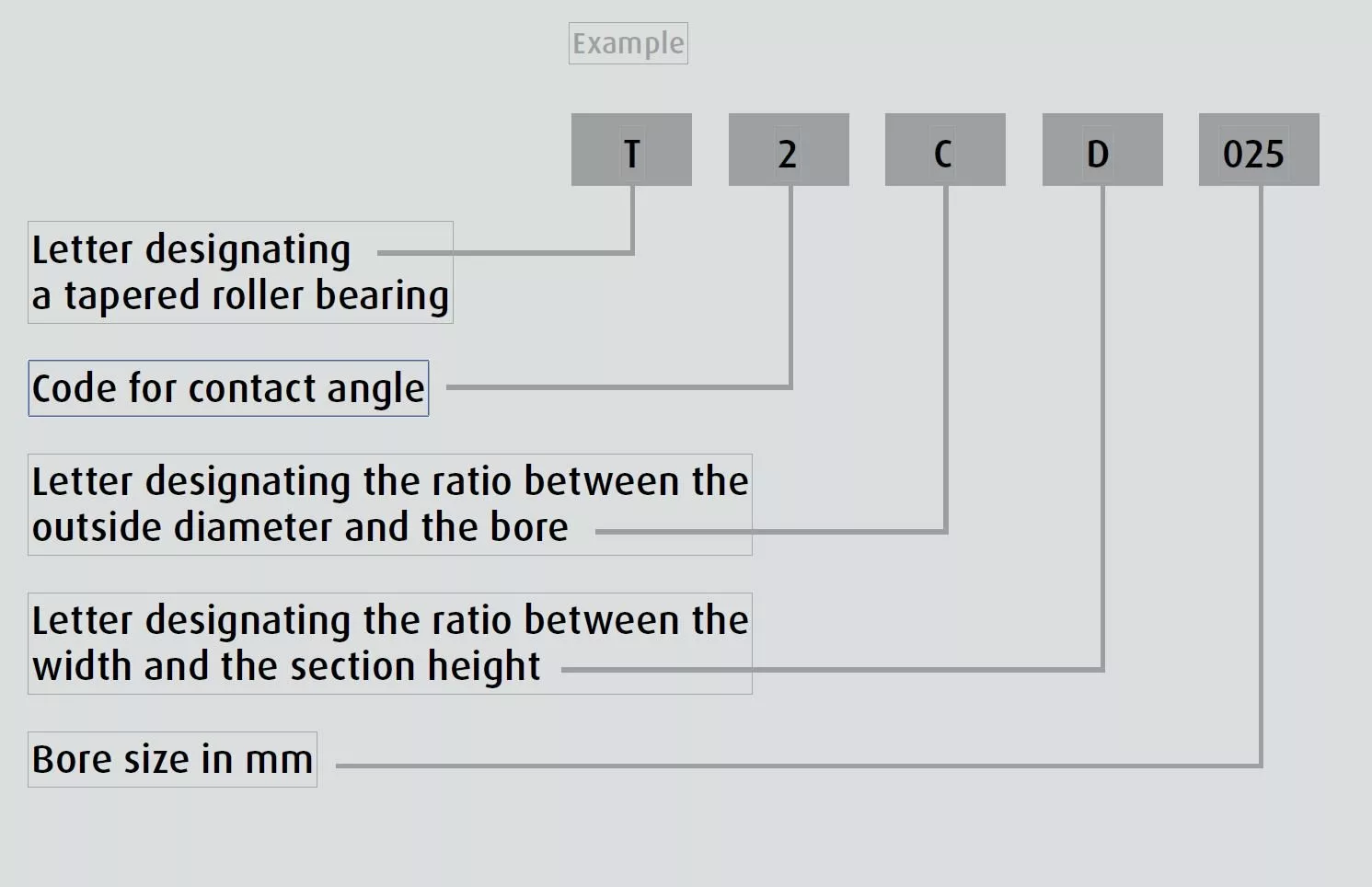

The diagram below shows how the order codes are made up. There should

be spaces separating the individual sections of an order code from one

another.

Designation of tapered roller bearings as per ISO 355

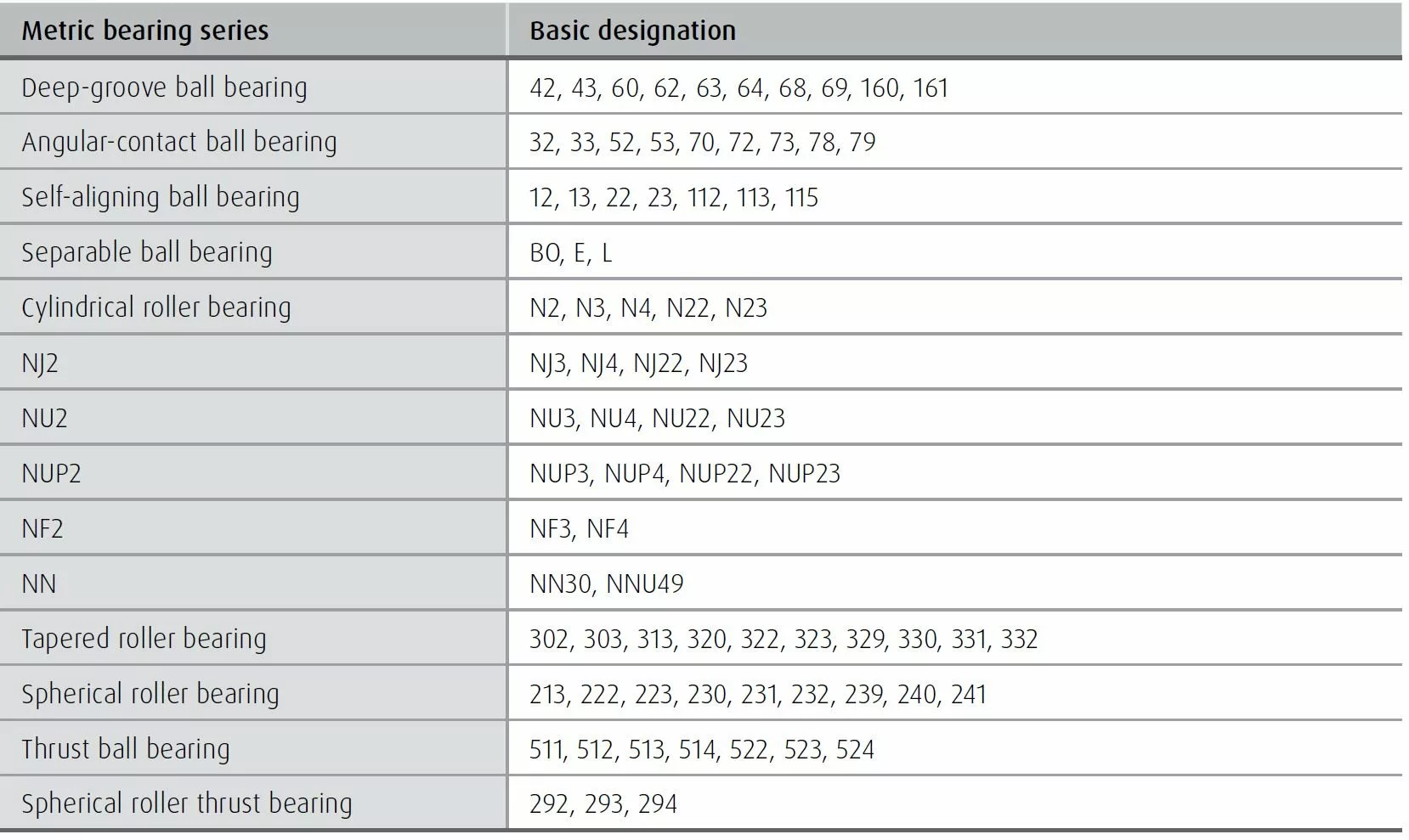

Basic Designations

The basic designation consists of the code for the bearing series and the code for the bearing bore. The most important codes for metric bearing series are listed in table 1.1.

Table 1.1 – Basic designations

Code for the bearing bore

The code for the bearing bore indicates the bearing’s bore size. A two-digit number is used for bore sizes from 20 mm to 480 mm. This number is multiplied by five to give the bore size. For example, the code 6224 stands for a deep-groove ball bearing with a bore size of 120 mm.

Diameters of 10, 12, 15 and 17 mm are an exception. In these cases, 00 indicates a diameter of 10 mm, 01 stands for 12 mm, 02 means 15 mm and the code 03 corresponds to a diameter of 17 mm.

The diameter is stated in mm for bore sizes up to 9 mm and over 480 mm. However, a deep-groove ball bearing with the code 688 MC3 has a bore size of 8 mm and a spherical roller bearing designated as 230/560 CAM E4 has a bore size of 560 mm.

The bore size is separated from the bearing series code using a slash in the case of bearings with bore sizes that cannot be divided by five, e.g. 63/22.

Letters and their different meanings

Prefixes and suffixes can have different meanings depending on the bearing series in question.

Examples:

- HR 33206 J Contact angle as per ISO

- 6204 ZZ C3E AS2S 5 J Individually wrapped and boxed

- 6304 C3 E Low noise bearing

- NJ 204 E T Extra capacity cylindrical roller bearing

- R NU 207 Cylindrical roller bearing with no inner ring

- R 4 ZZ Miniature bearing with imperial dimensions

Use of codes on bearings and packaging

The full bearing code – including all prefixes and suffixes – always appears on the packaging. The bearing rings themselves usually only feature the basic designation and some supplementary designations, such as radial clearance and accuracy.

Information about the cage is not normally provided on the rings. Should a replacement bearing be needed, users have to check the bearing which has been removed to see what type of cage is required. The lubricant used in sealed deepgroove ball bearings, for example, cannot be indicated on the bearing itself due to the large number of different options available.

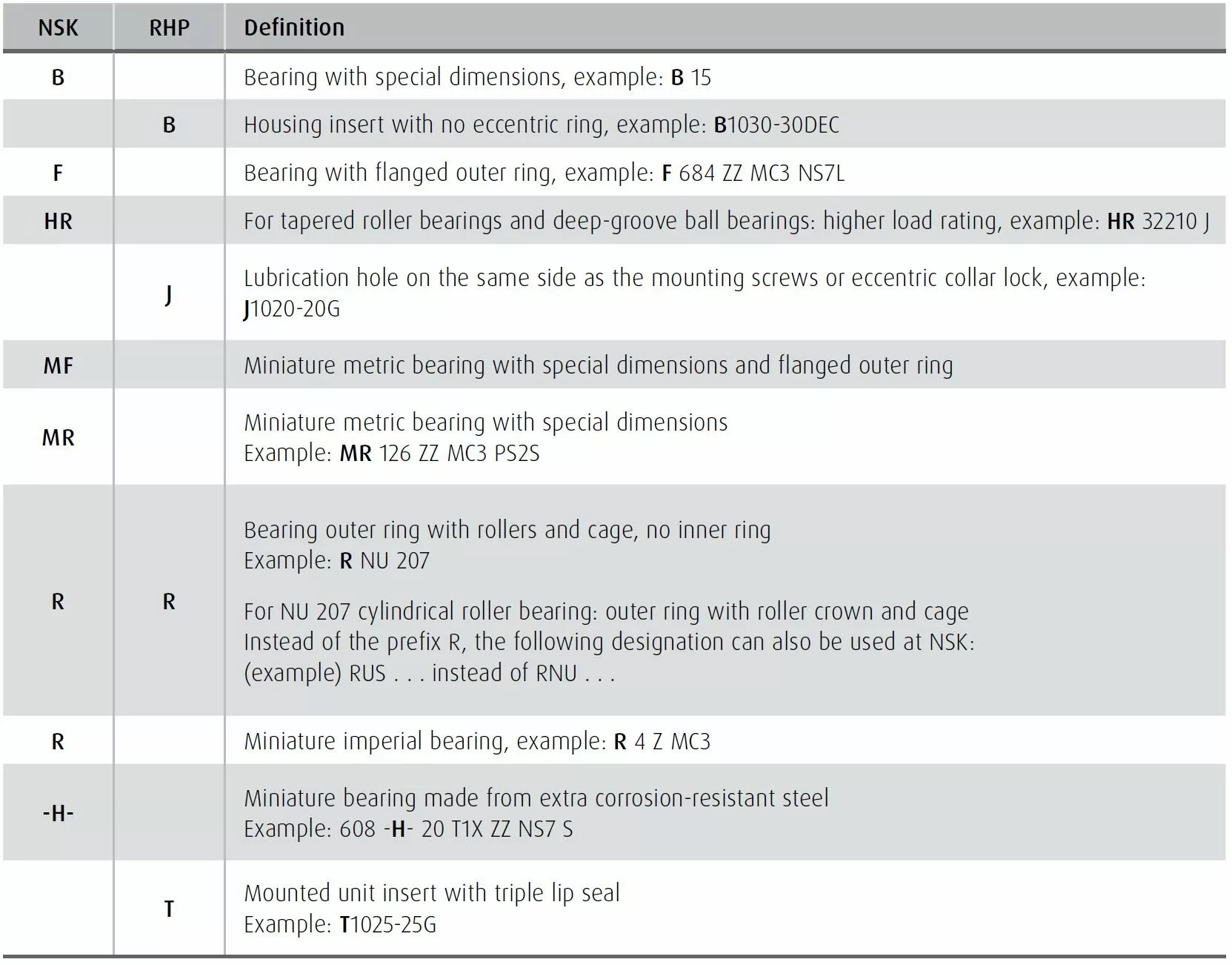

Prefixes

Prefixes are used comparatively rarely. They serve almost exclusively to indicate individual components of complete bearings or to designate miniature bearings. The codes are listed in table 2.

Table 2 – Prefixes at a glance

A large number of suffixes are used to denote structural modifications. Specifically, the suffixes provide information about the:

Gage Type

- Internal design

- Seal

- Lubricant used

- Tolerances

- Internal clearance

- External design

The suffixes are listed in table 3.

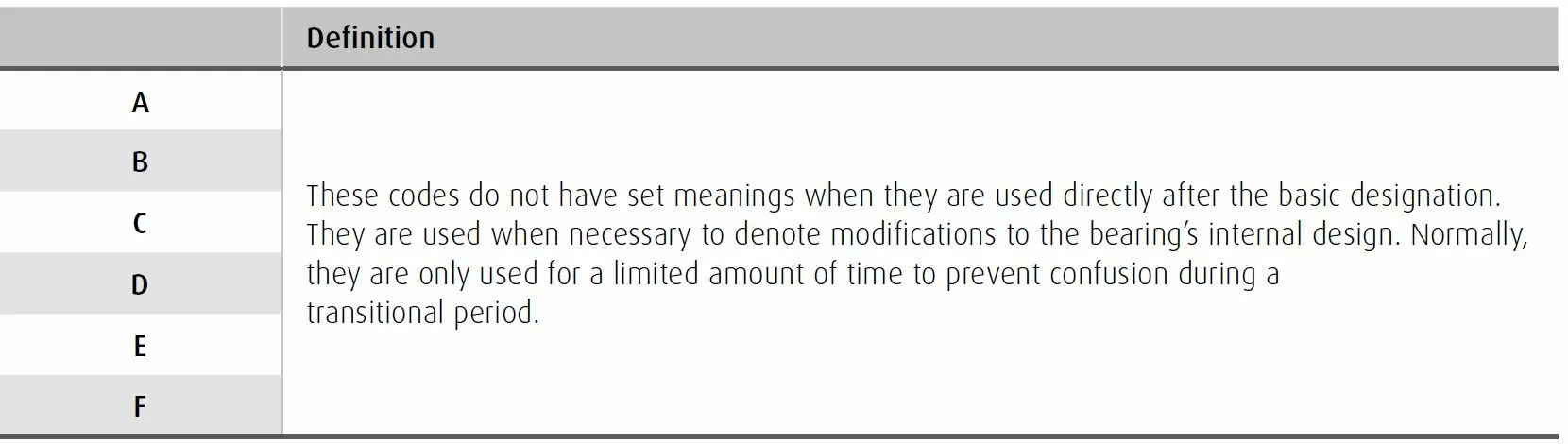

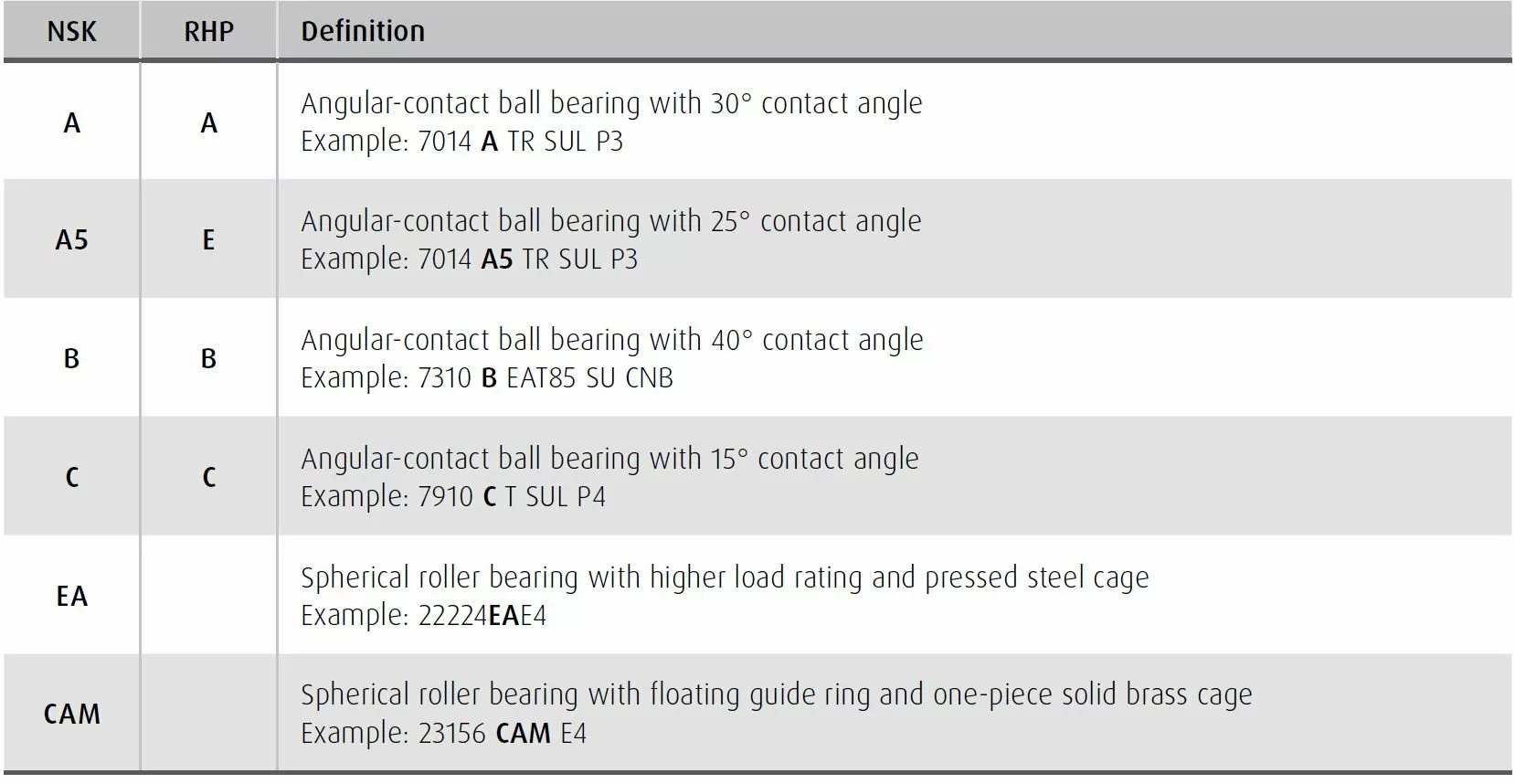

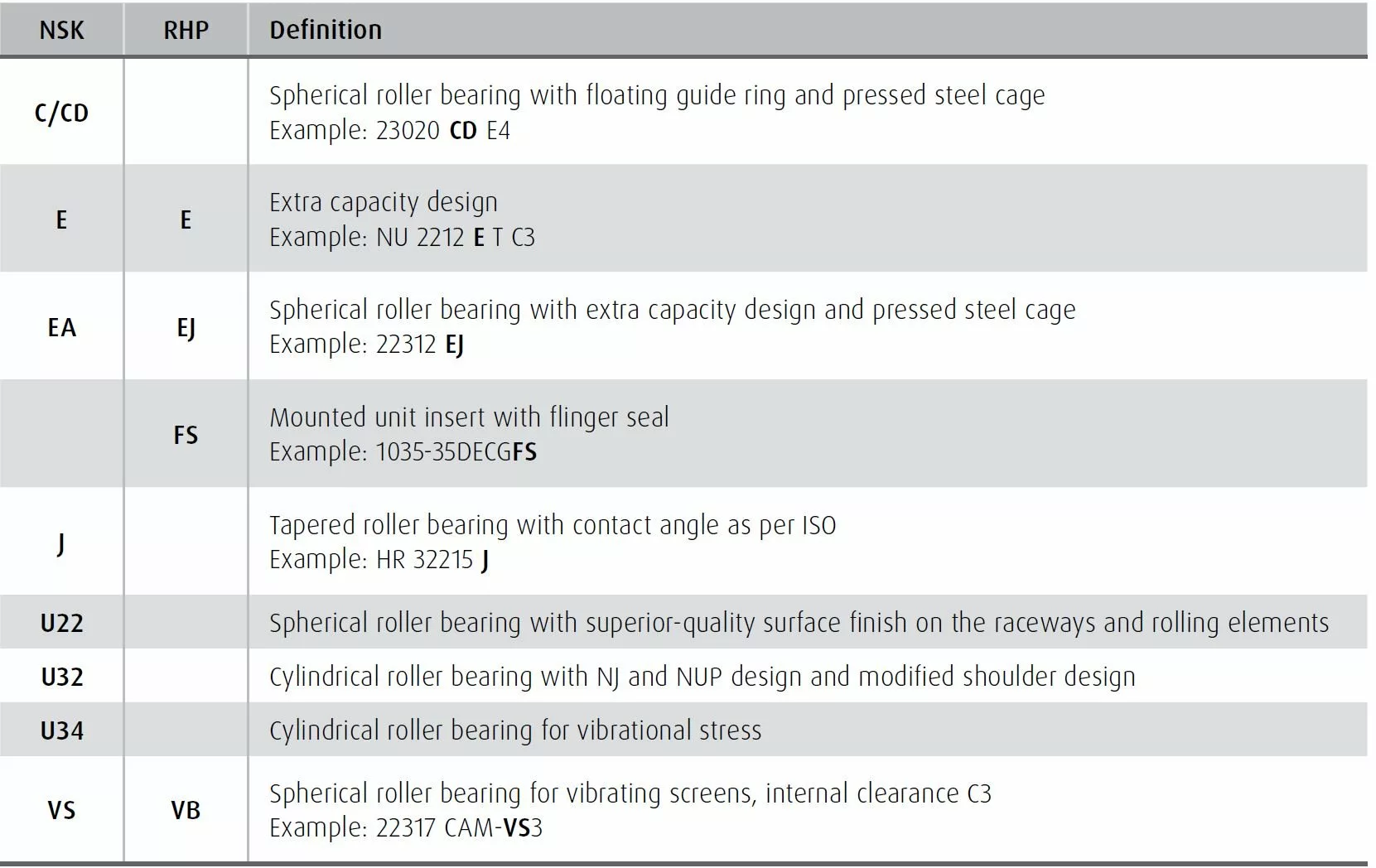

Table 3.1 – Internal design

However, in some cases they are used permanently to designate bearings of the same type and dimensions which have different internal designs.

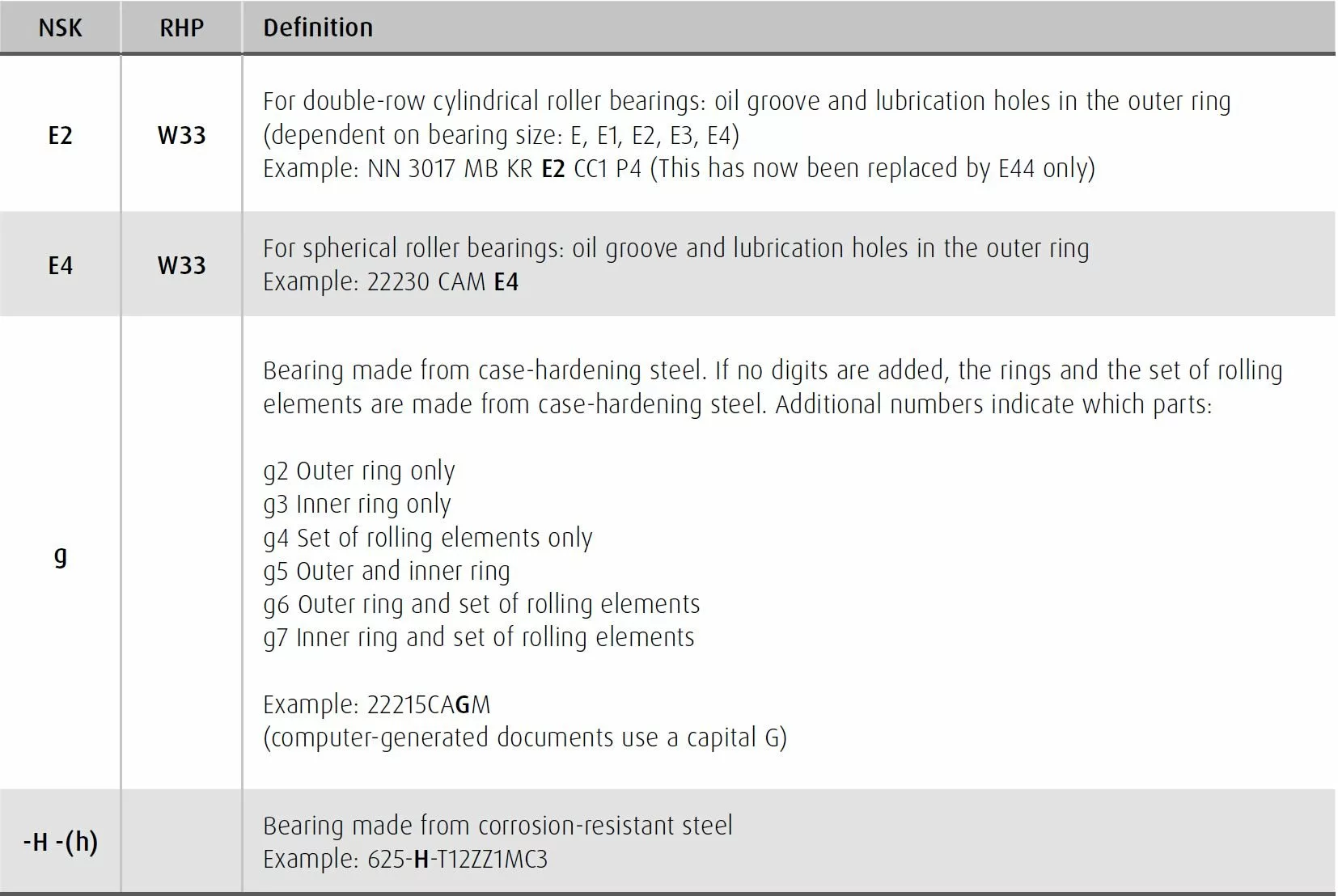

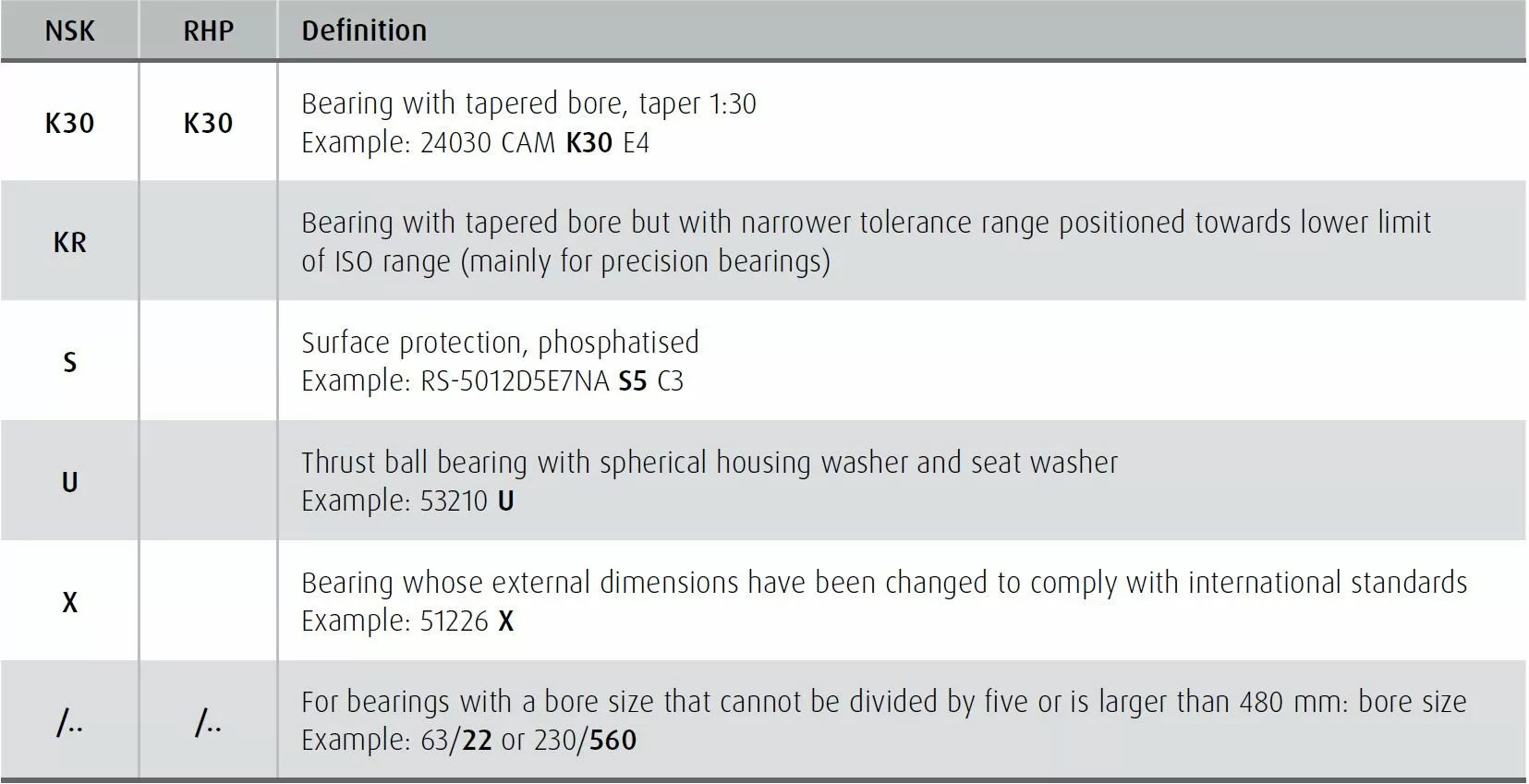

Table 3.2 – External dimensions, external design and materials

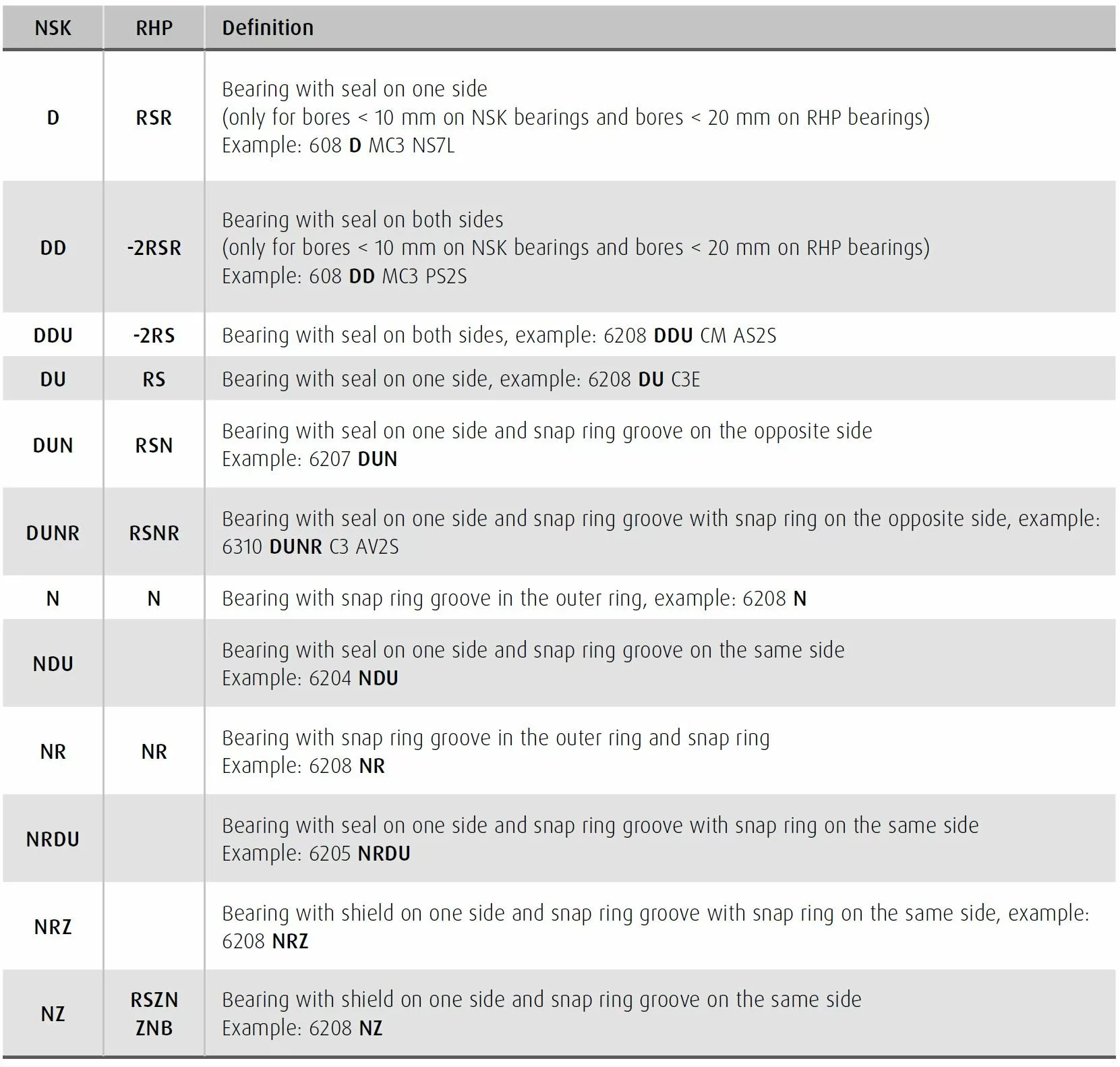

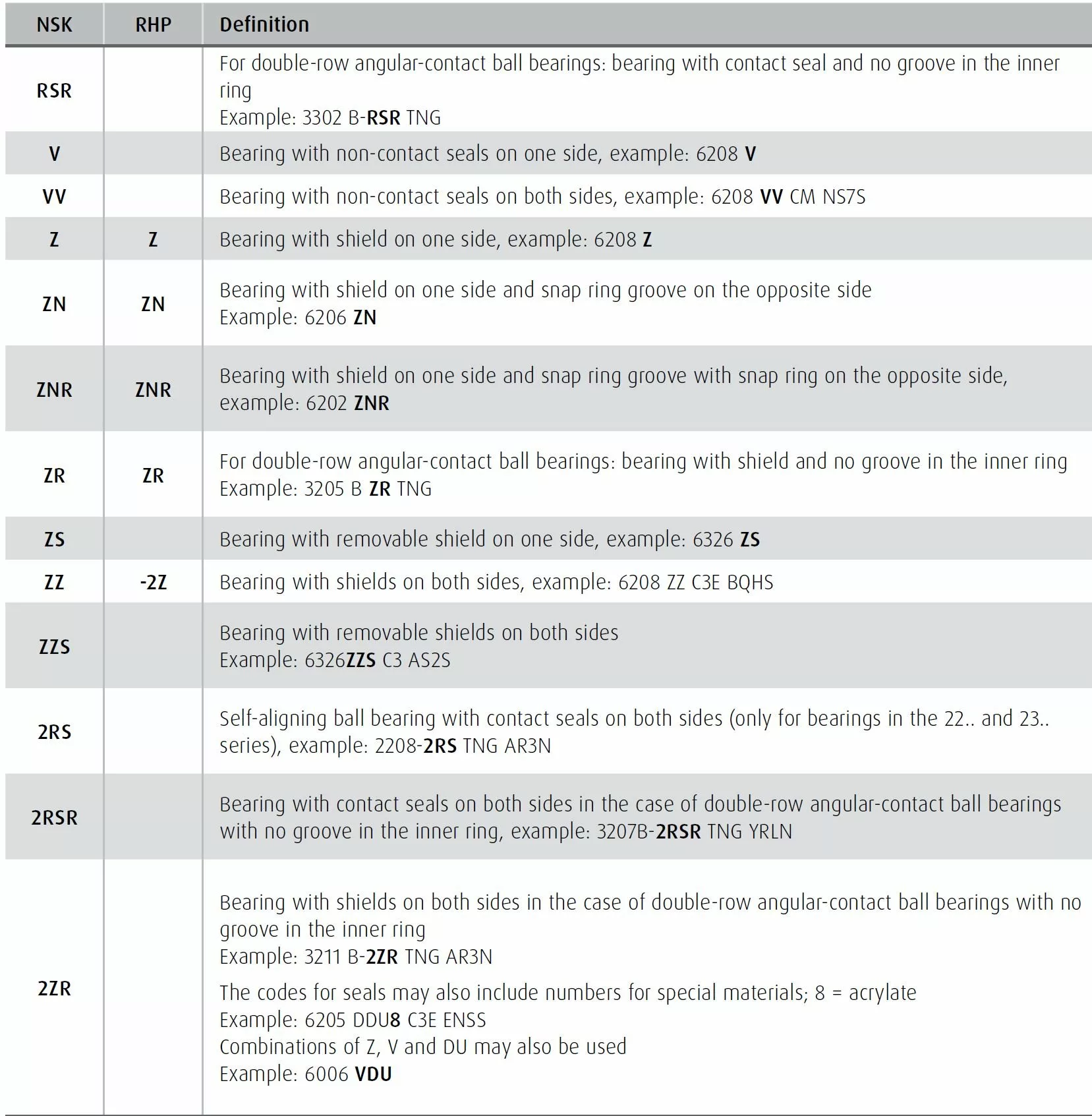

Table 3.3 – Seal and snap ring groove

The following suffixes are only used in conjunction with ball bearings.

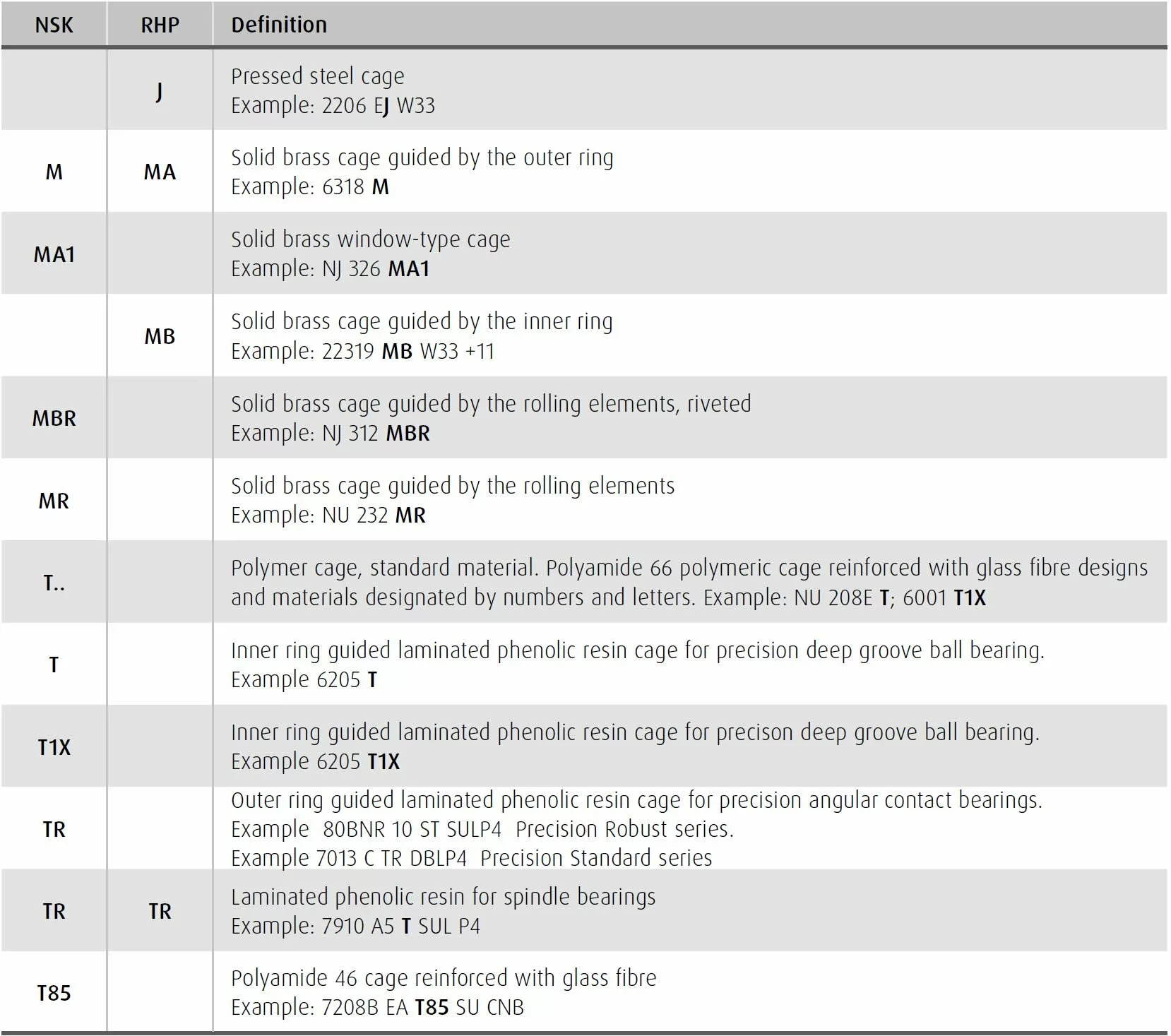

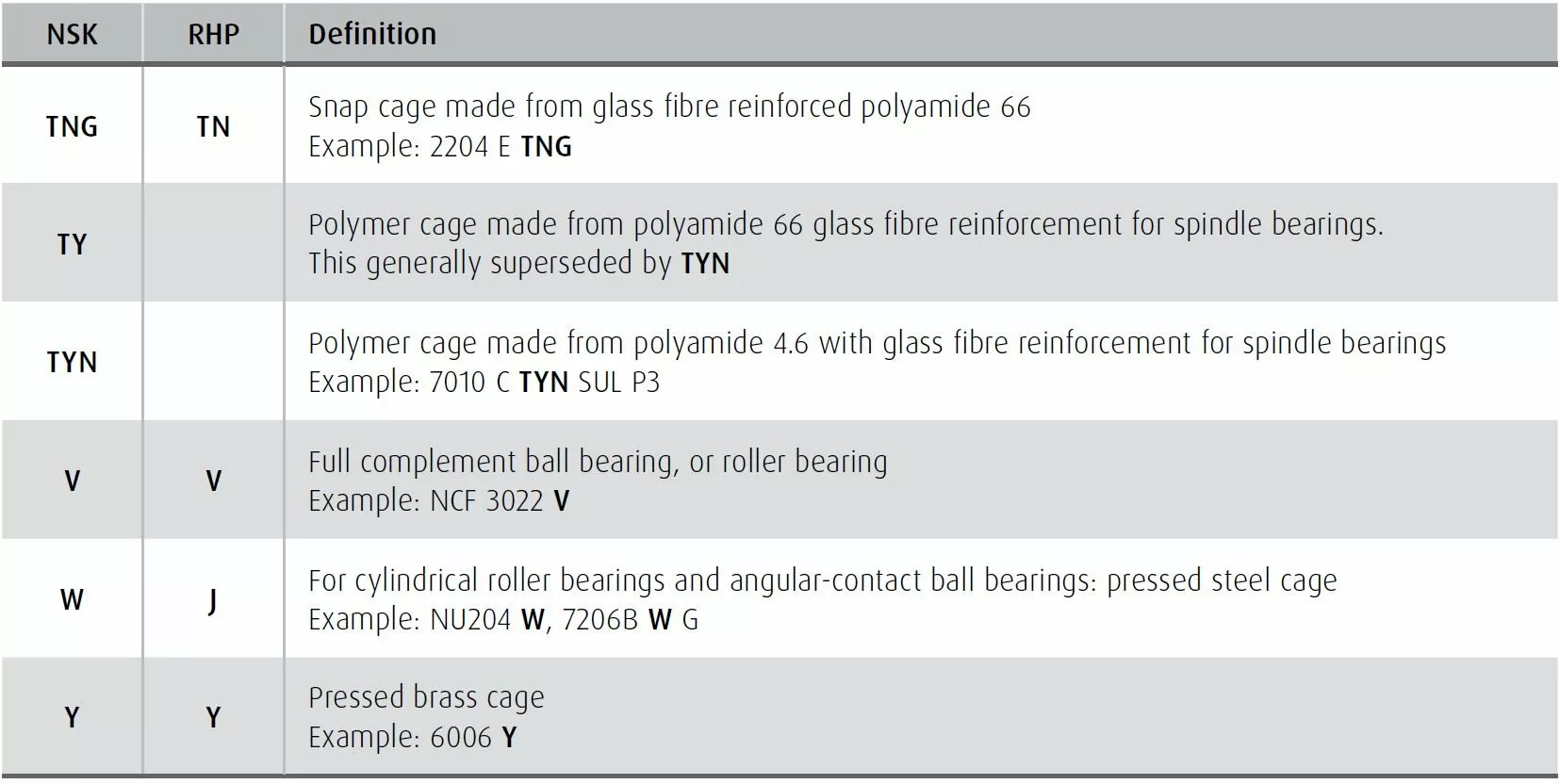

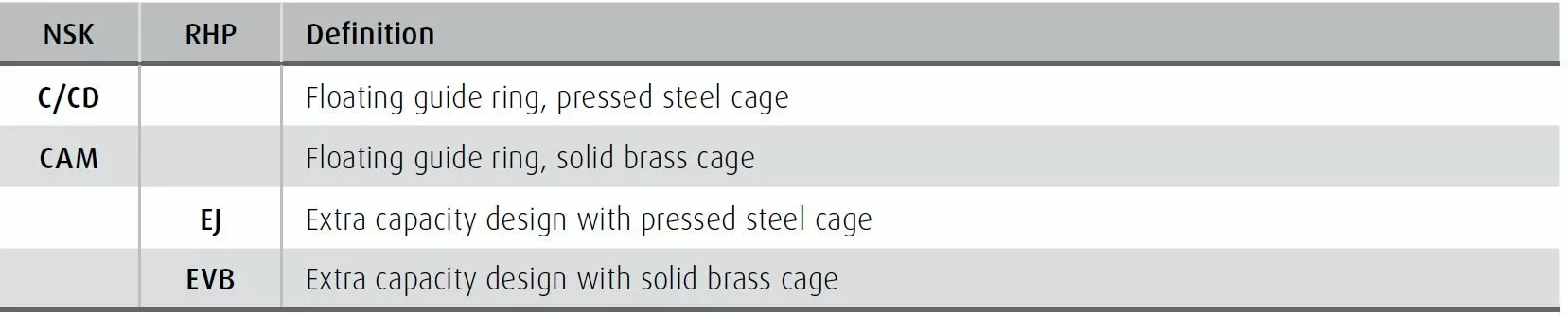

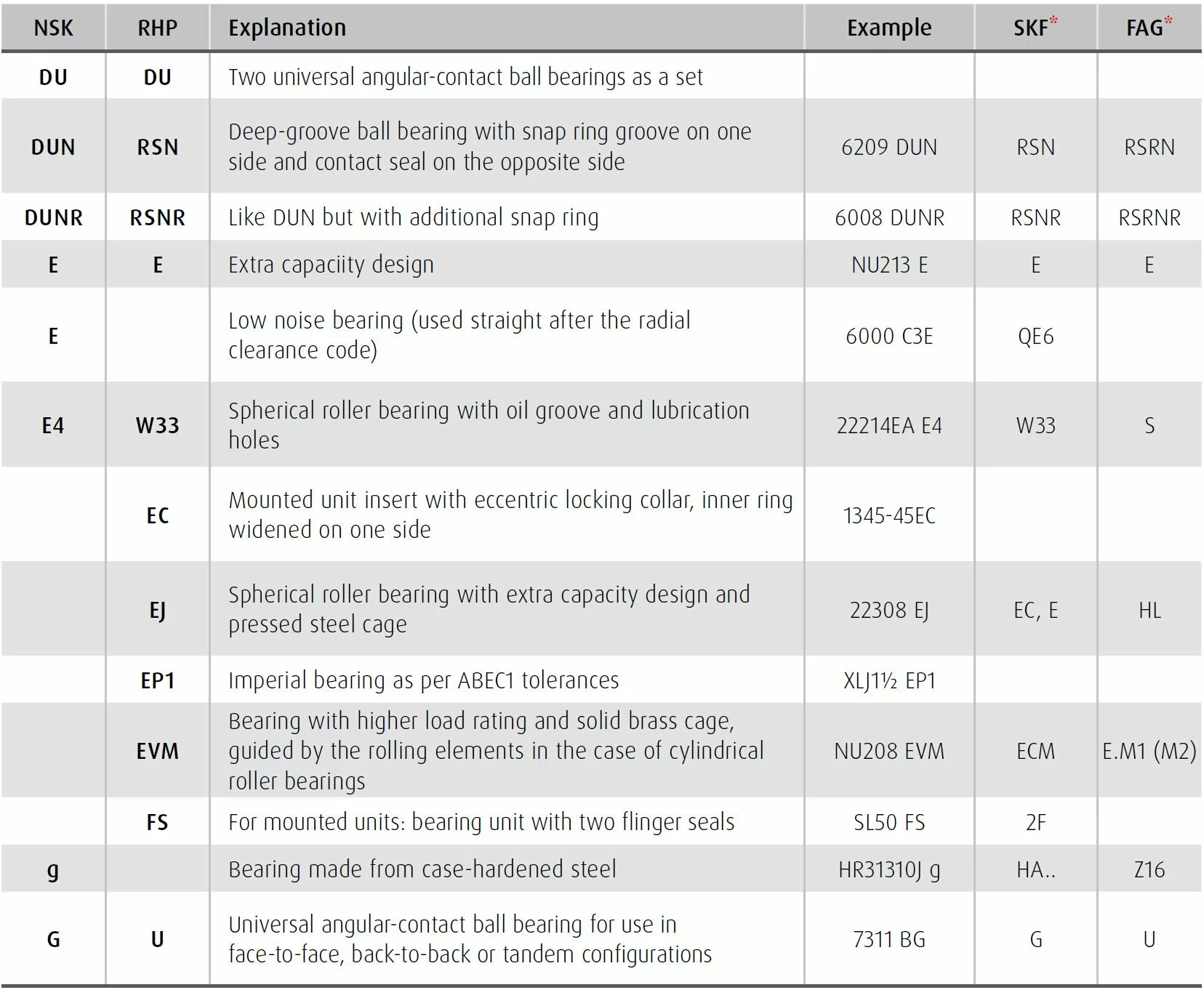

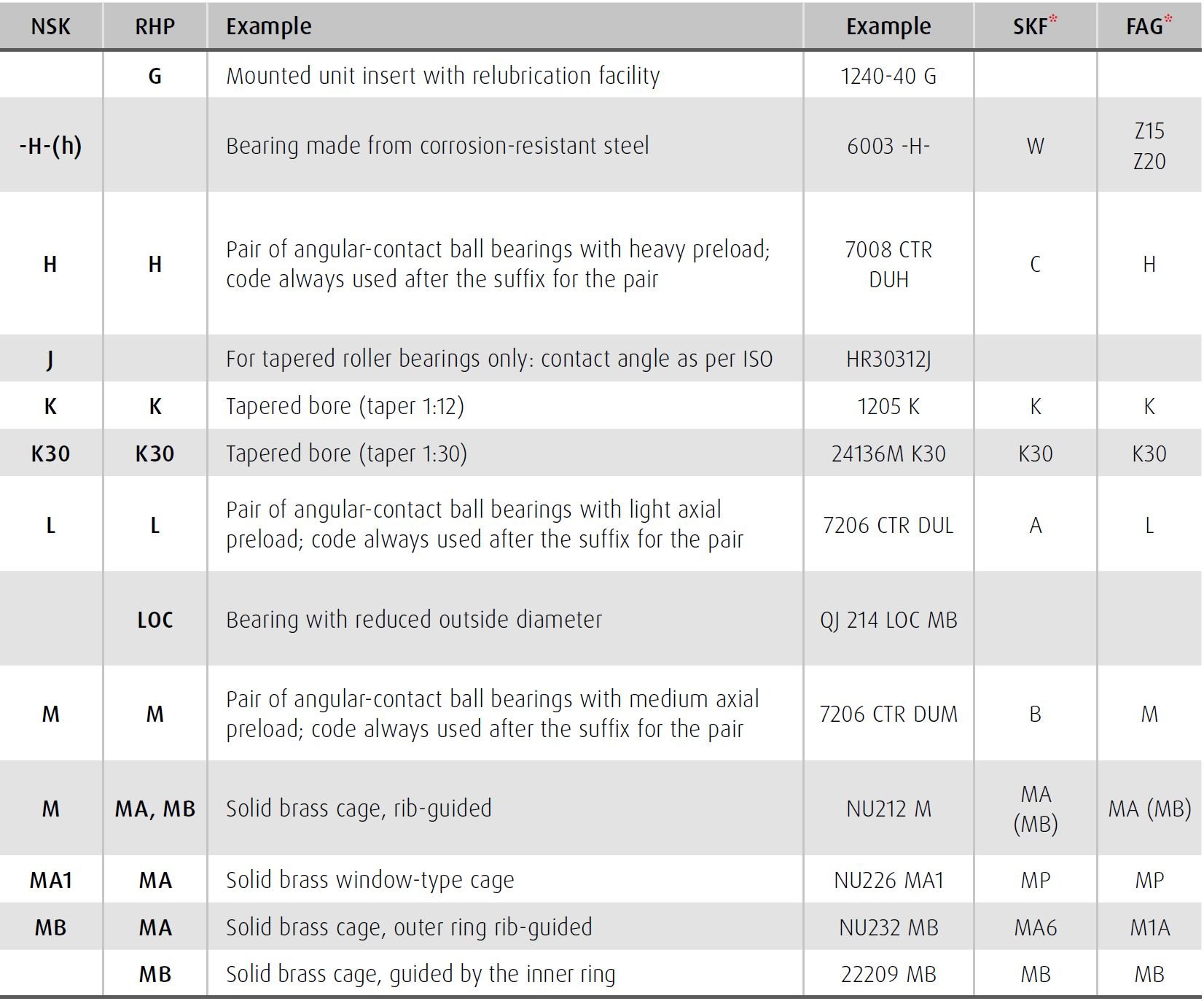

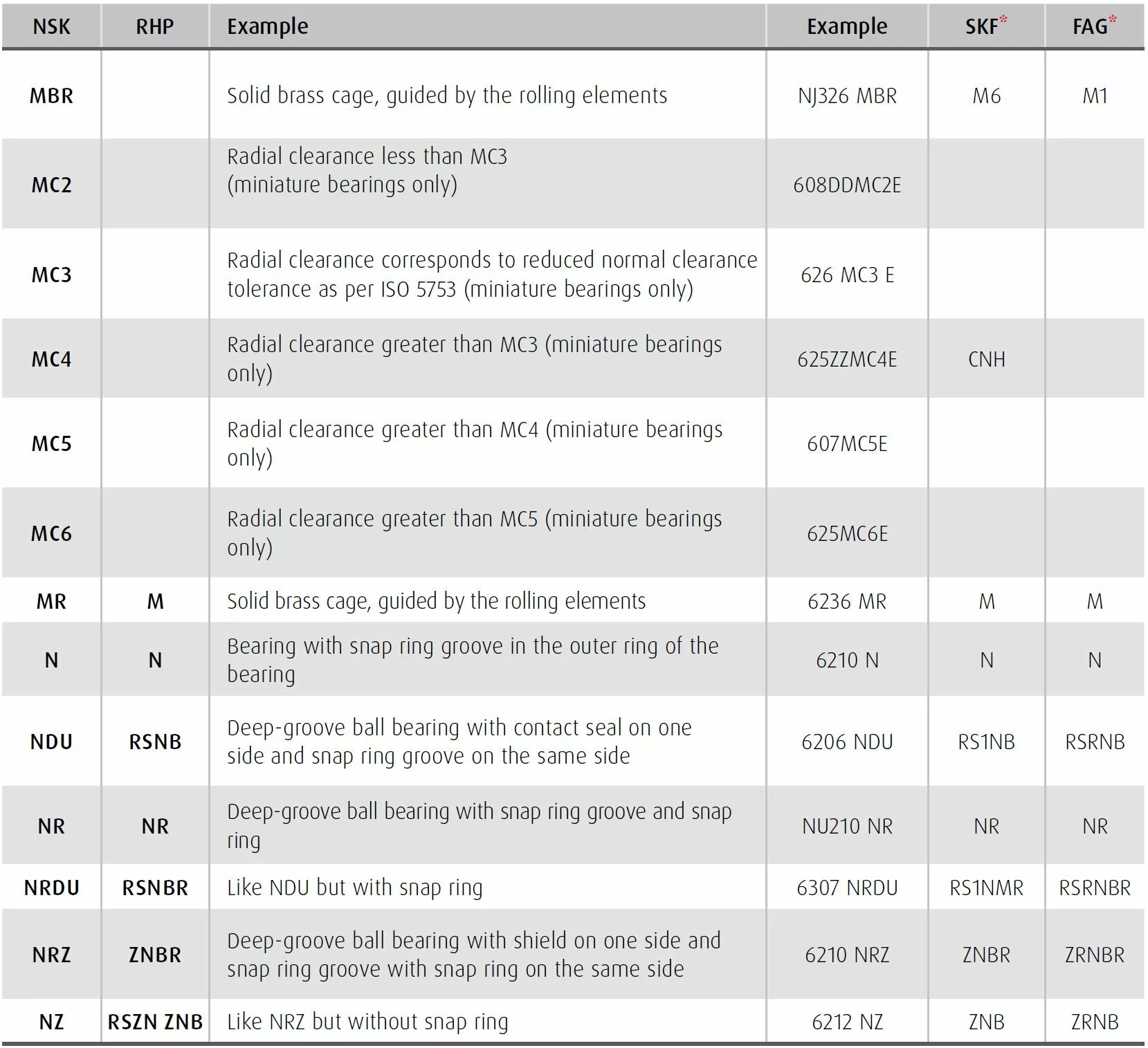

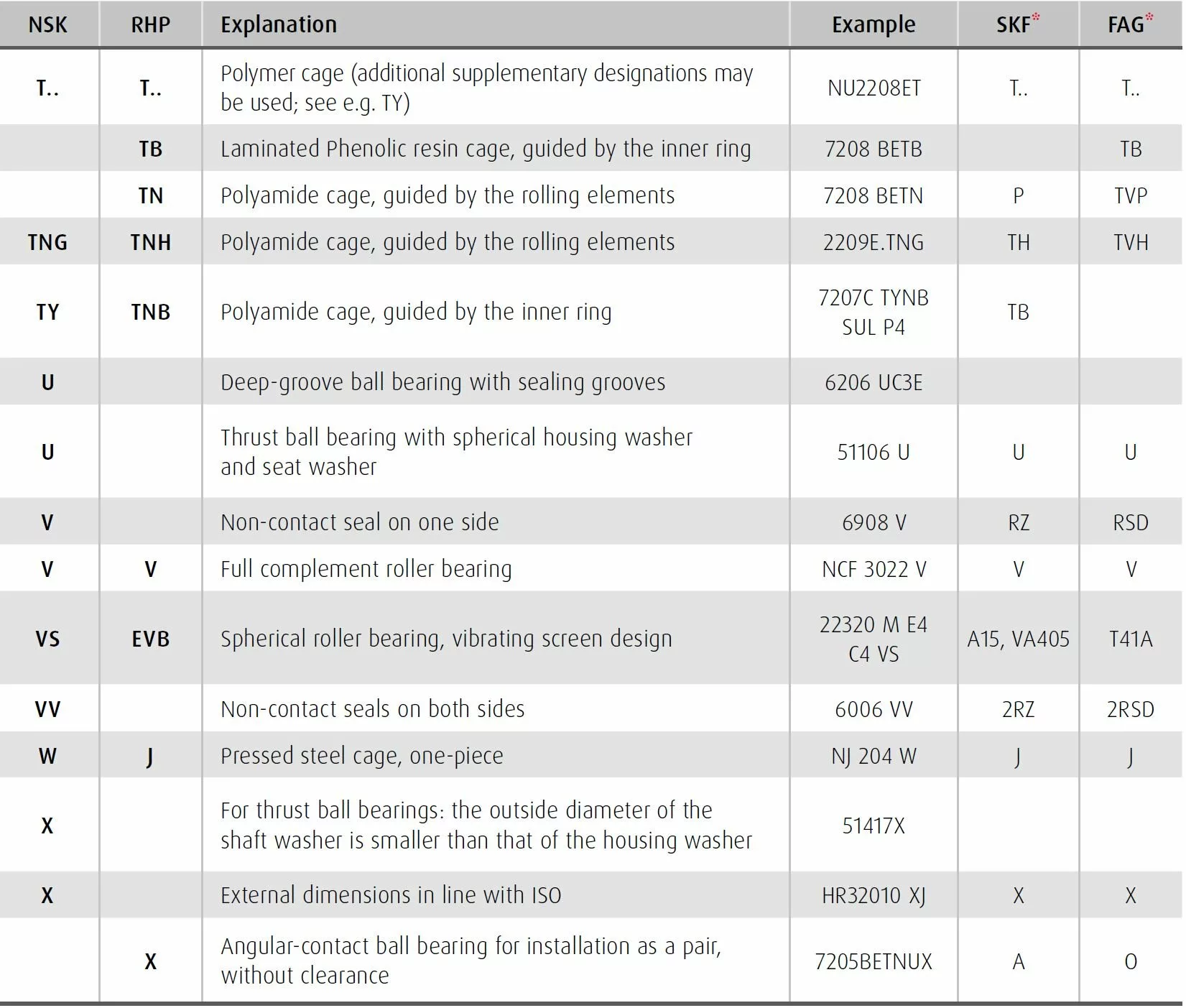

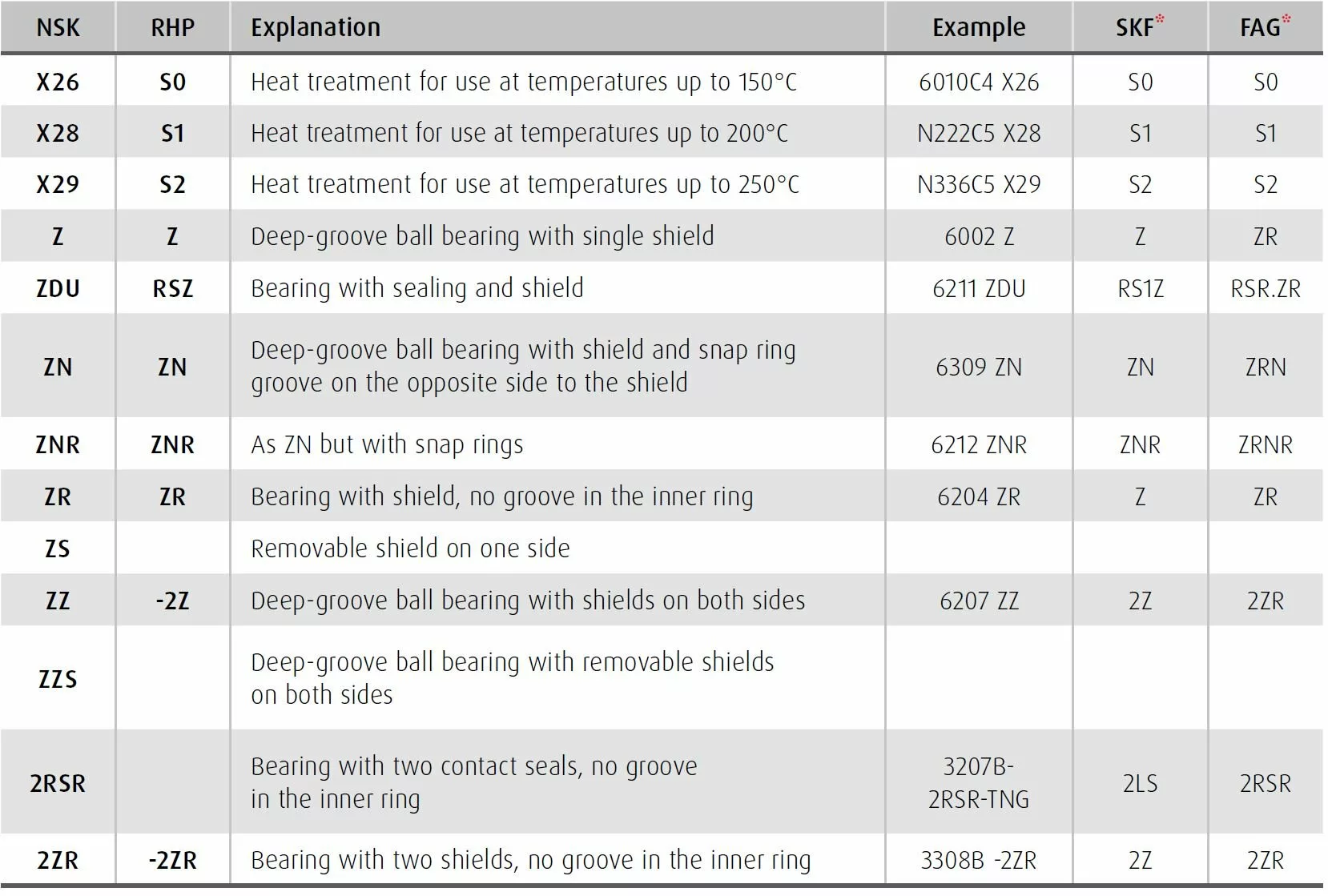

Table 3.4 – Cage type

The supplementary designation for the cage type is usually added on the end of the basic designation if the bearing does not feature the cage used as standard for the respective kind of bearing.

Table 3.4.1 – bearing design and cage type for spherical roller bearings

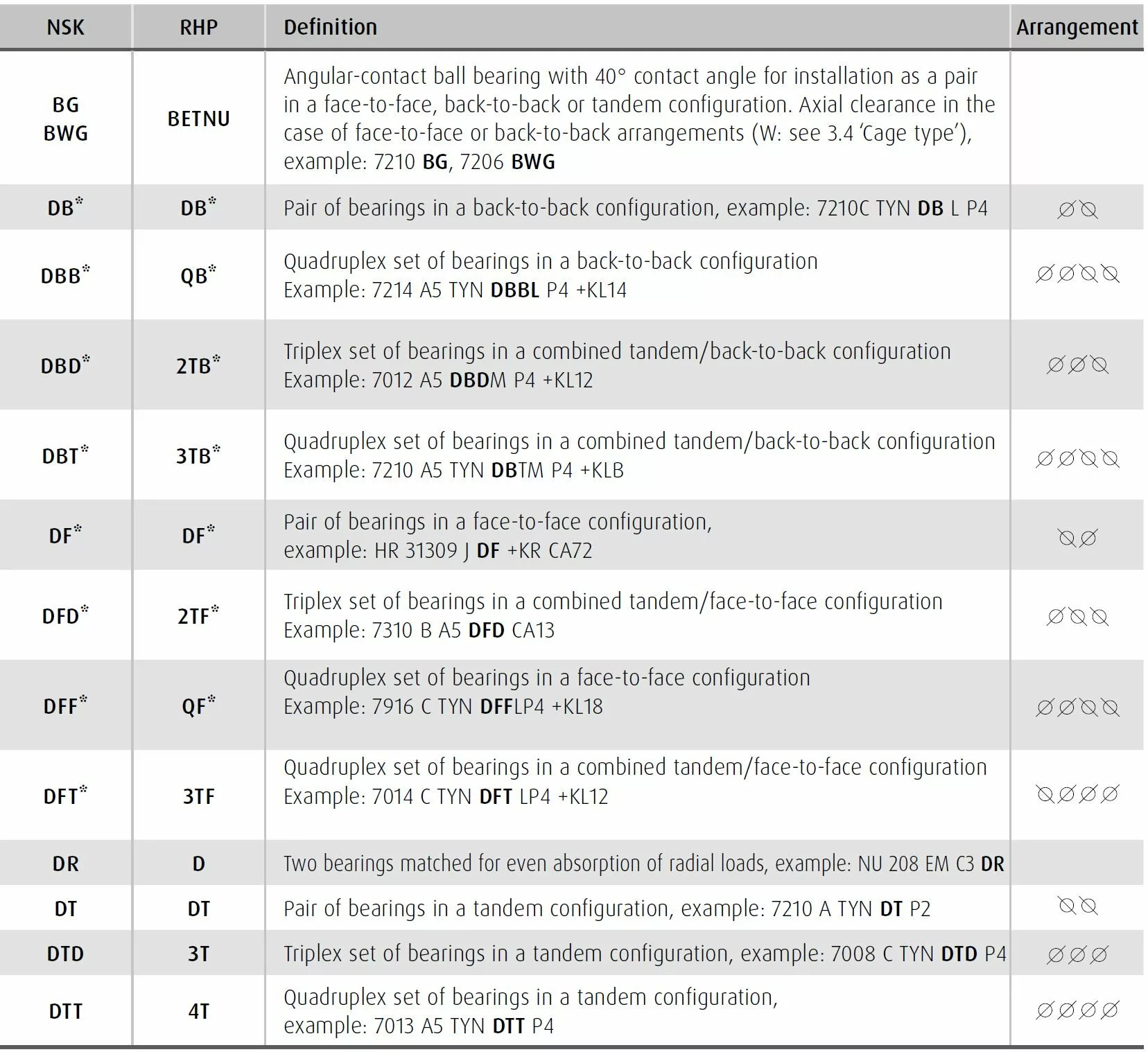

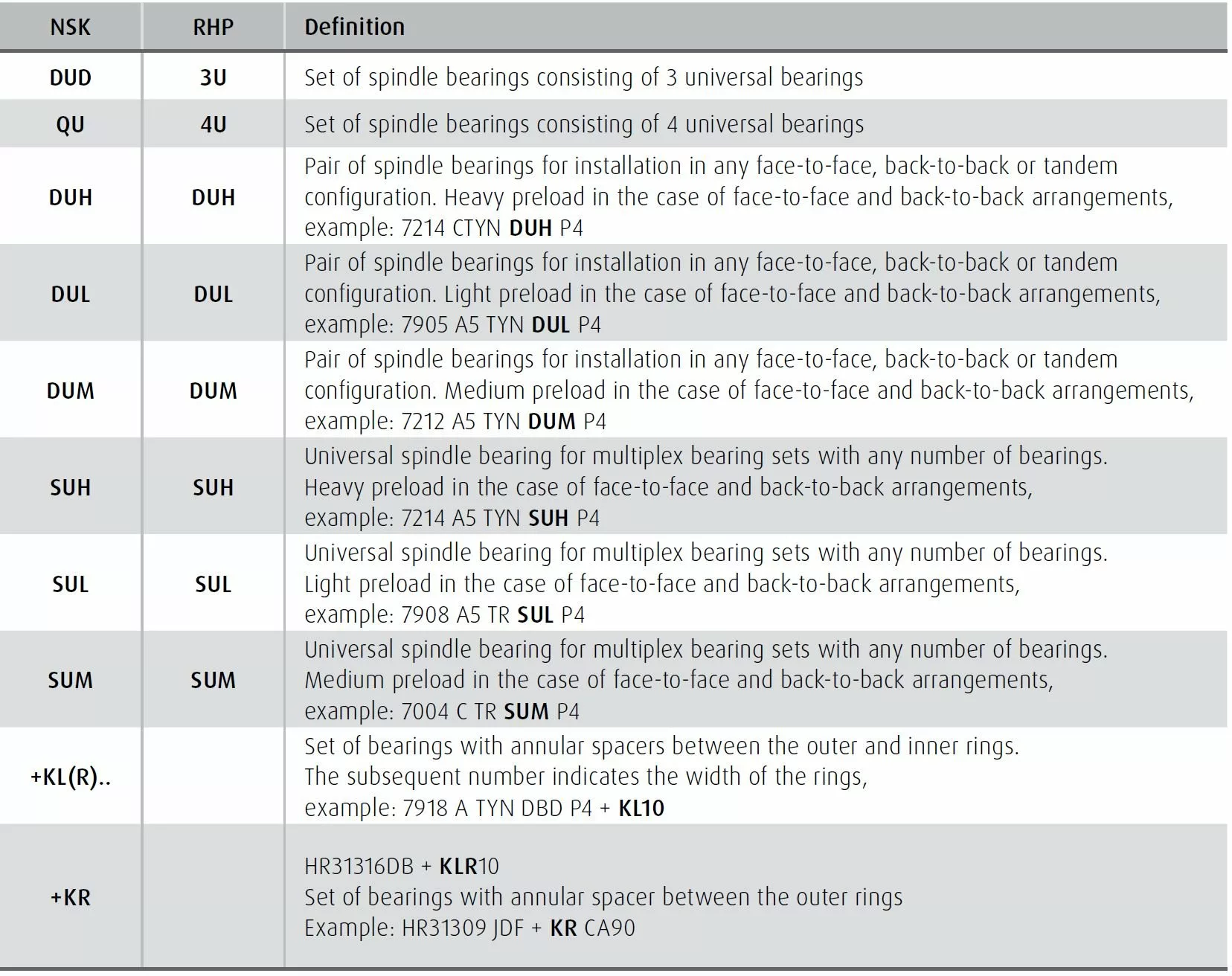

Table 3.5 – Matched bearings

A letter (L, M or H) is added to the codes marked with * to indicate the preload class. The same principle applies to SUL, SUM and SUH. For details of the special characters for internal clearance and preload, refer to 3.6 ‘Internal clearance’.

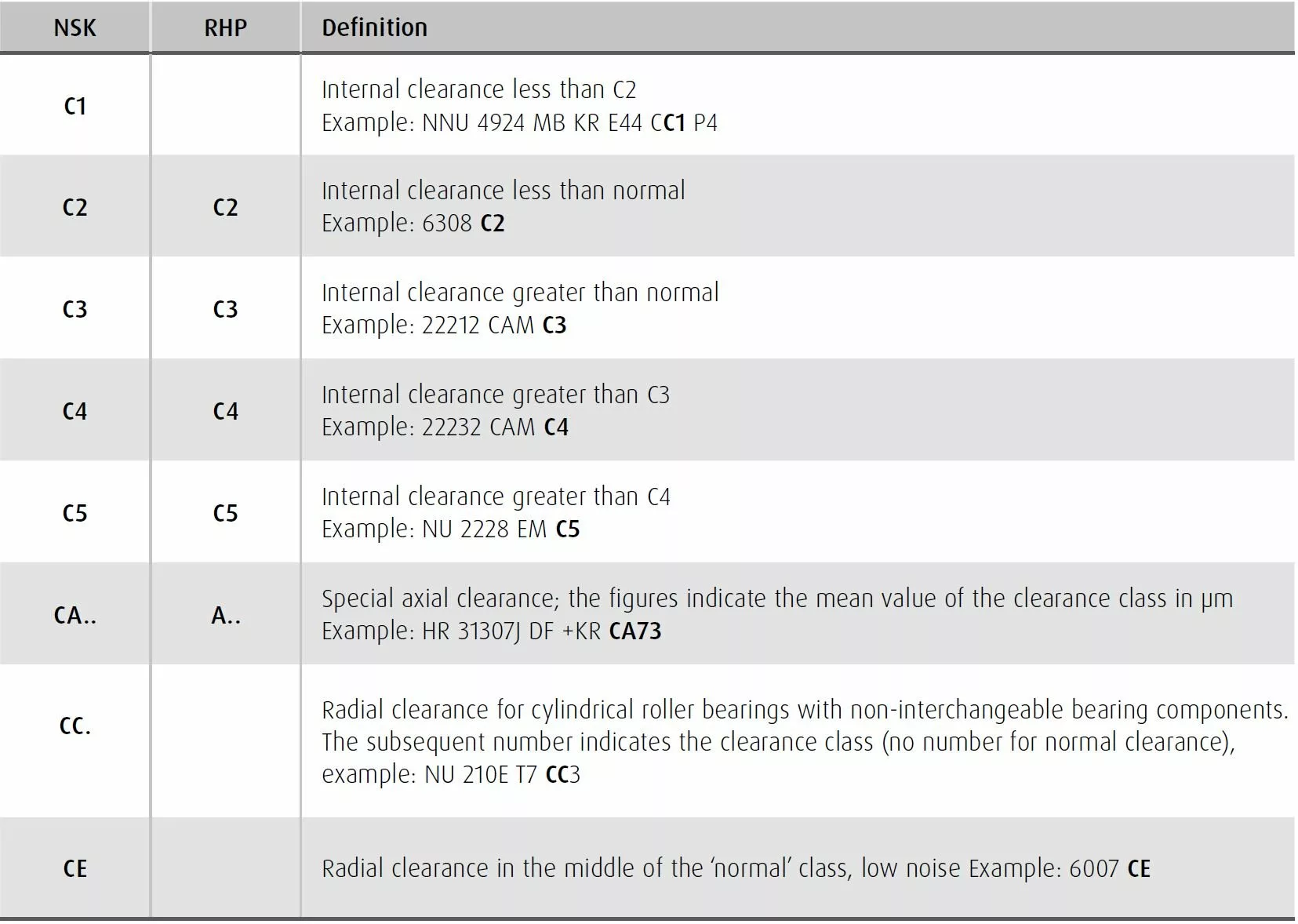

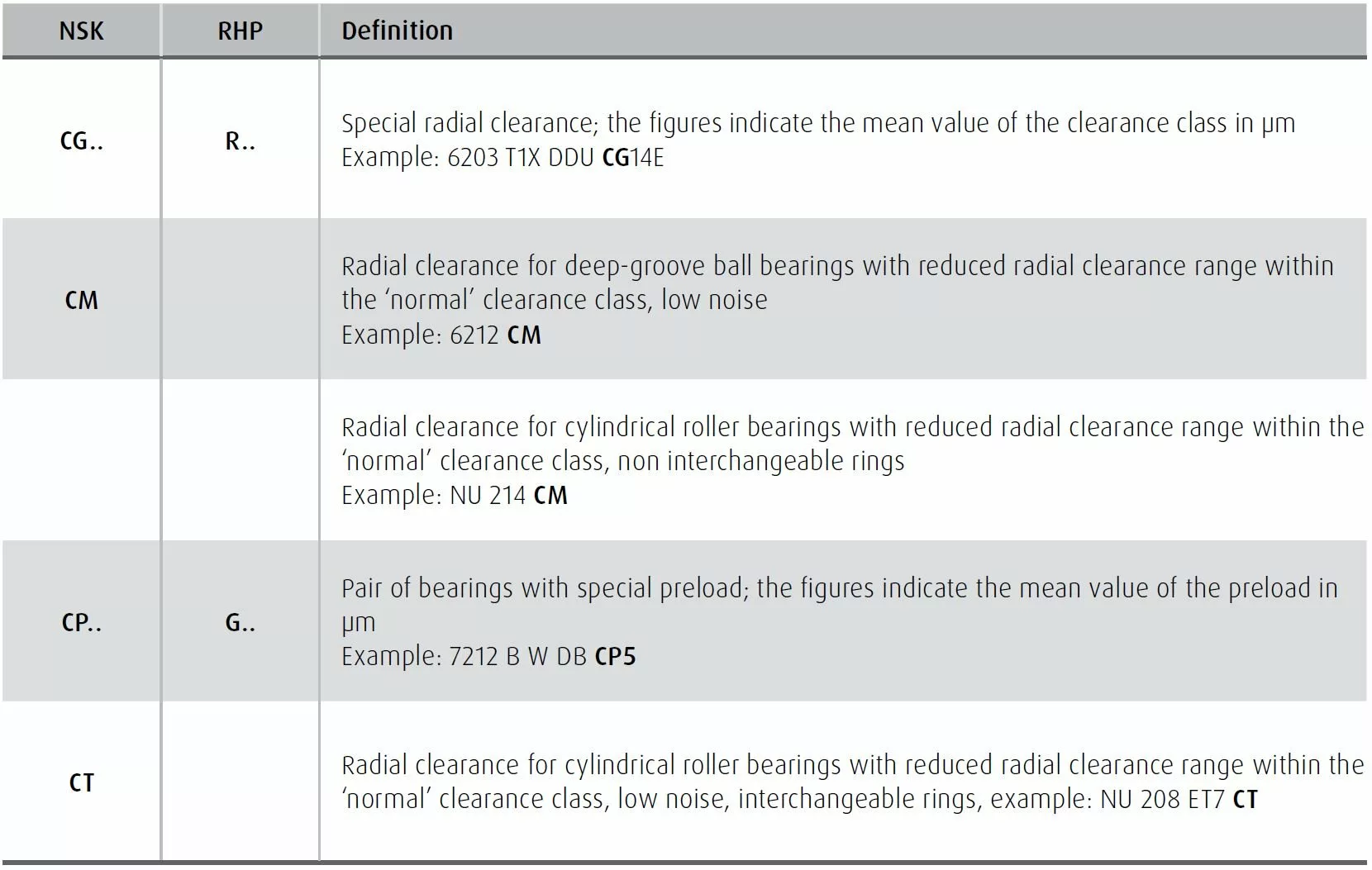

Table 3.6 – Internal clearance

C0 (or CN) denotes normal internal clearance and is not marked on the bearings themselves or on the packaging.

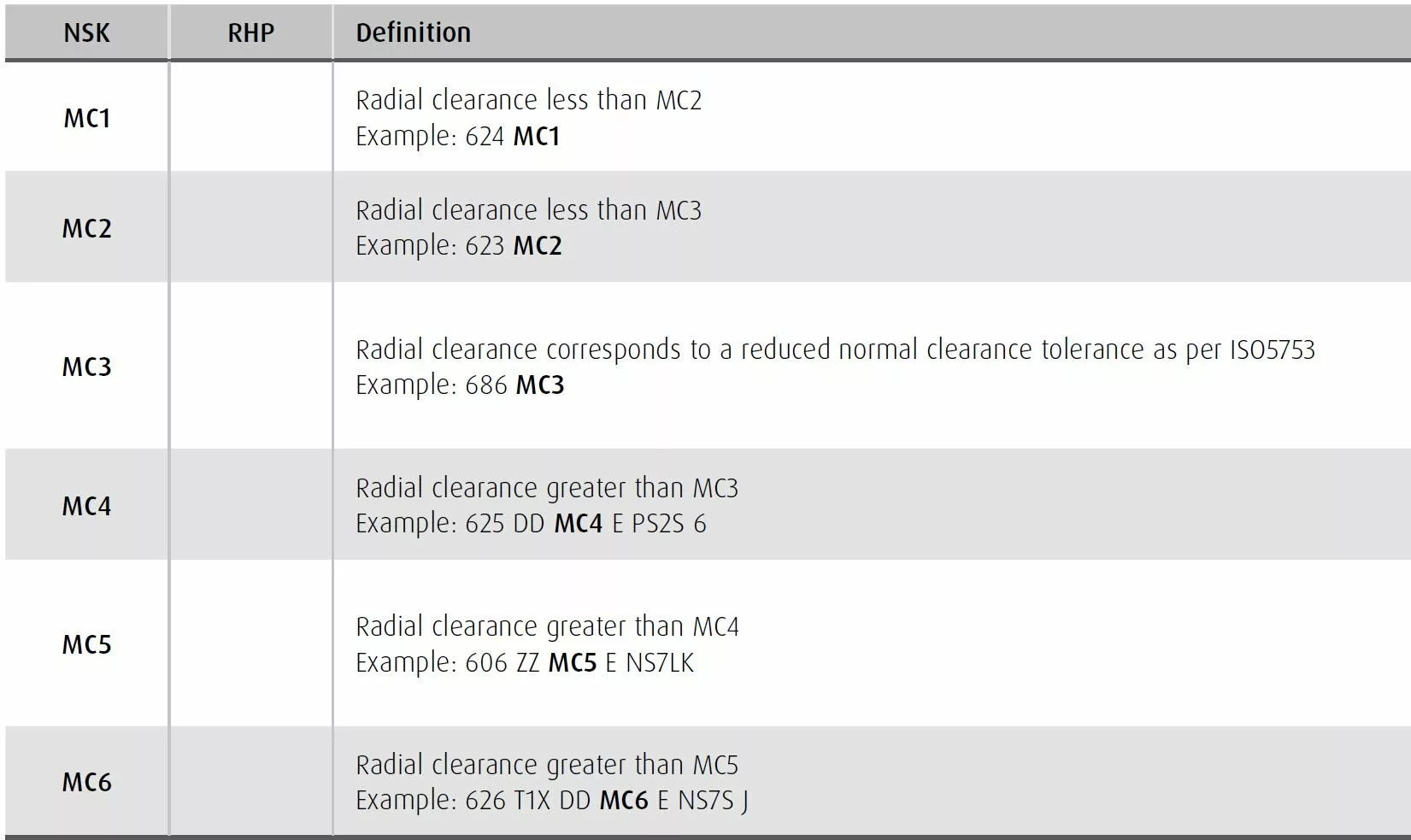

Table 3.7 – Internal clearance for deep-groove ball bearings with a bore size of less than 10 mm (miniature bearings)

Contrary to the radial clearance stipulations of ISO 5753 (see 4 ‘Suffixes: a comparison between NSK/RHP and two competitors’ codes’), NSK produces deep-groove ball bearings with a bore size of less than 10 mm to smaller tolerance ranges than those defined in the above-mentioned standard. MC3 radial clearance corresponds to reduced normal clearance as per ISO 5753. The radial clearance class of NSK miniature bearings is always indicated.

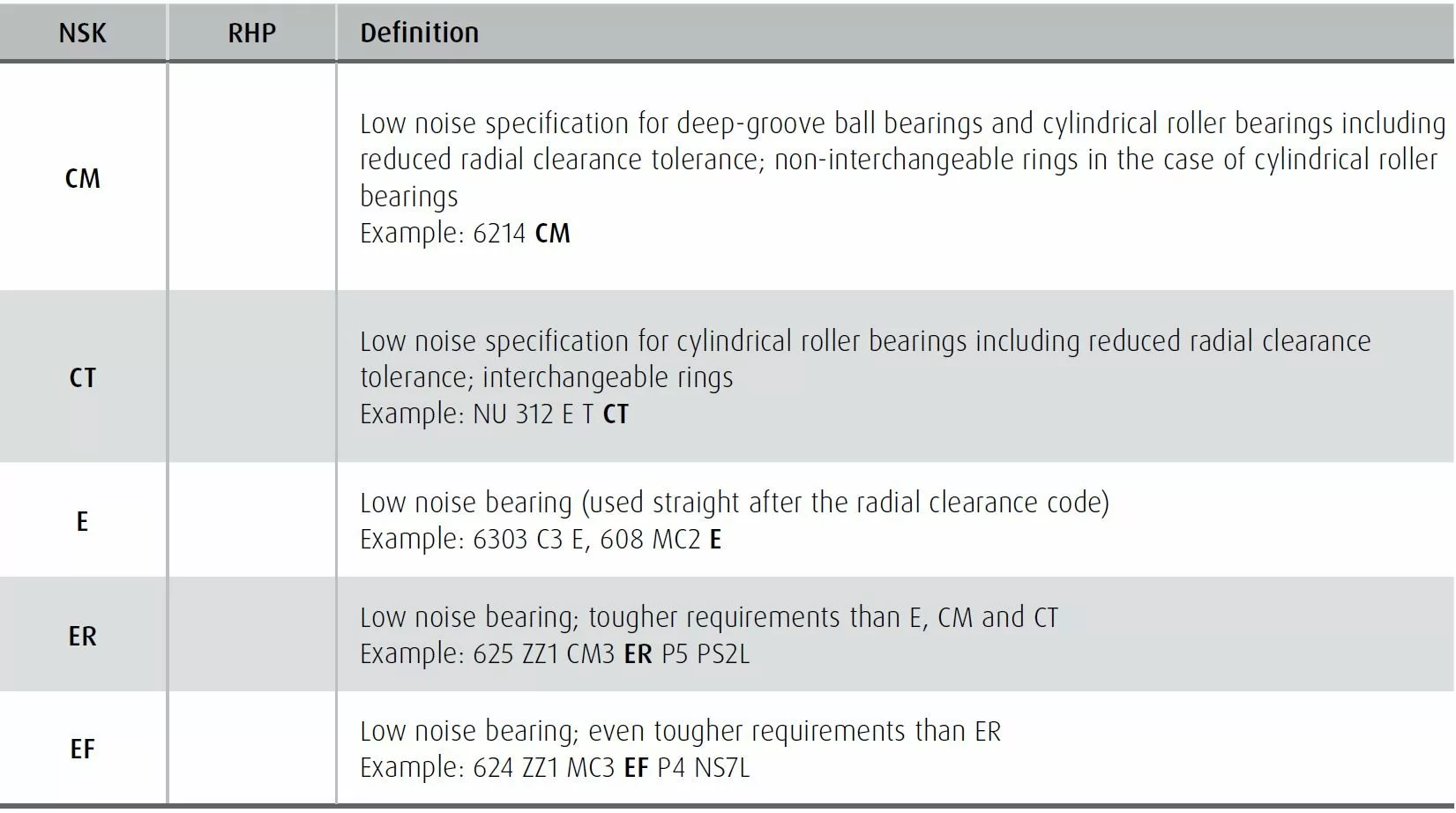

Table 3.8 – Noise-tested bearings

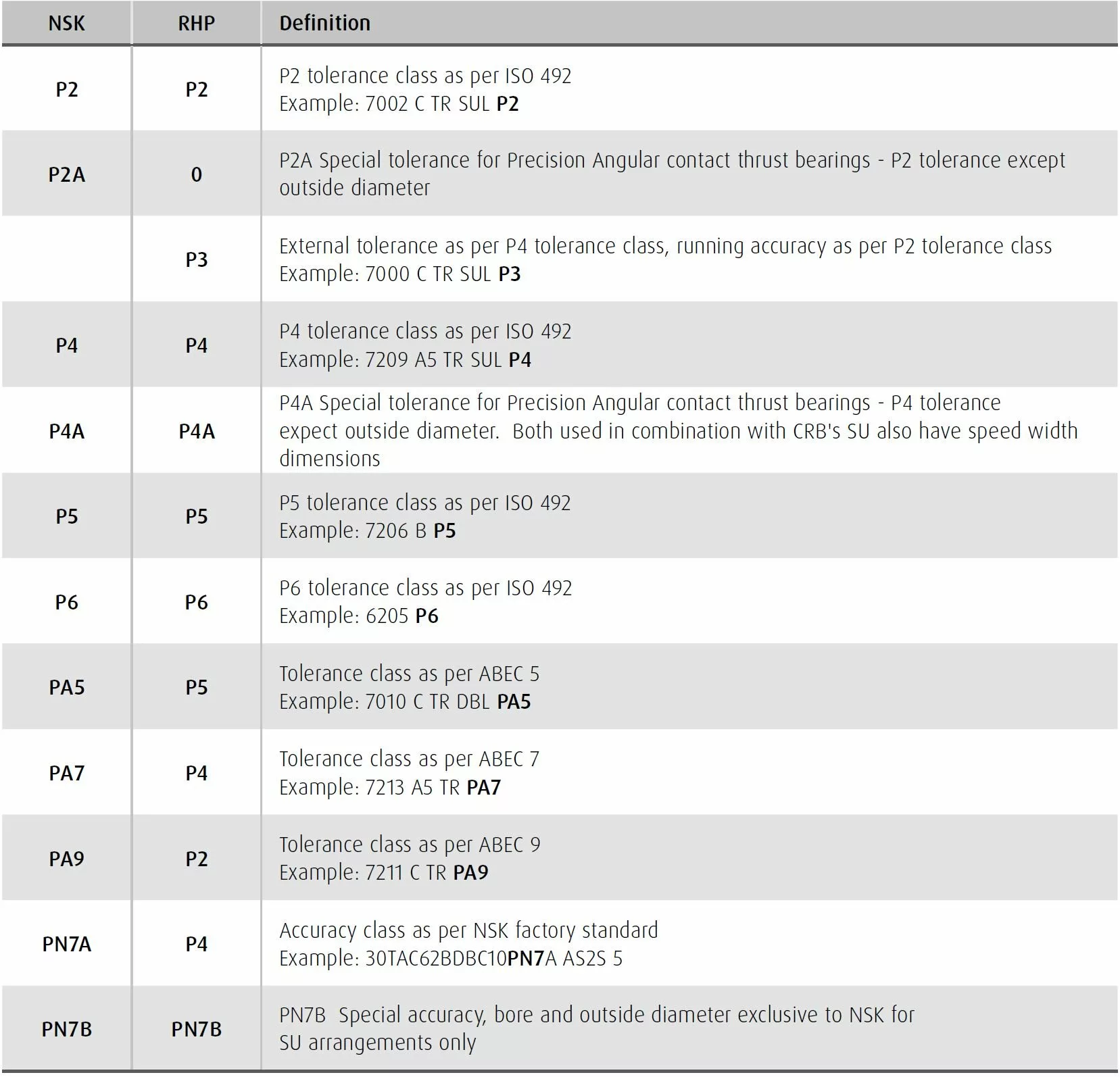

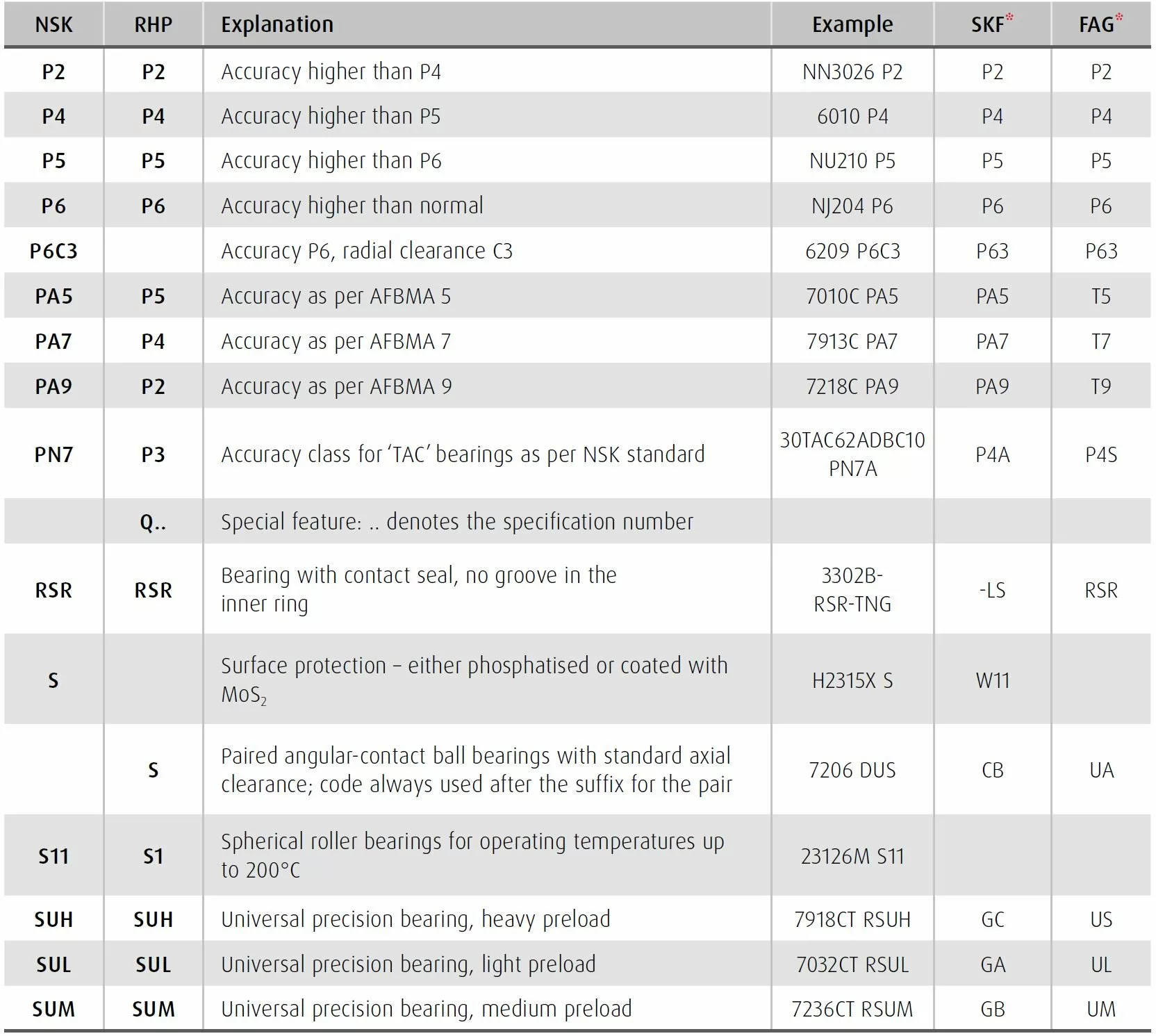

Table 3.9 – Dimensional, geometrical and running accuracy

Normal tolerance (P0) is not marked on the bearing or on the packaging.

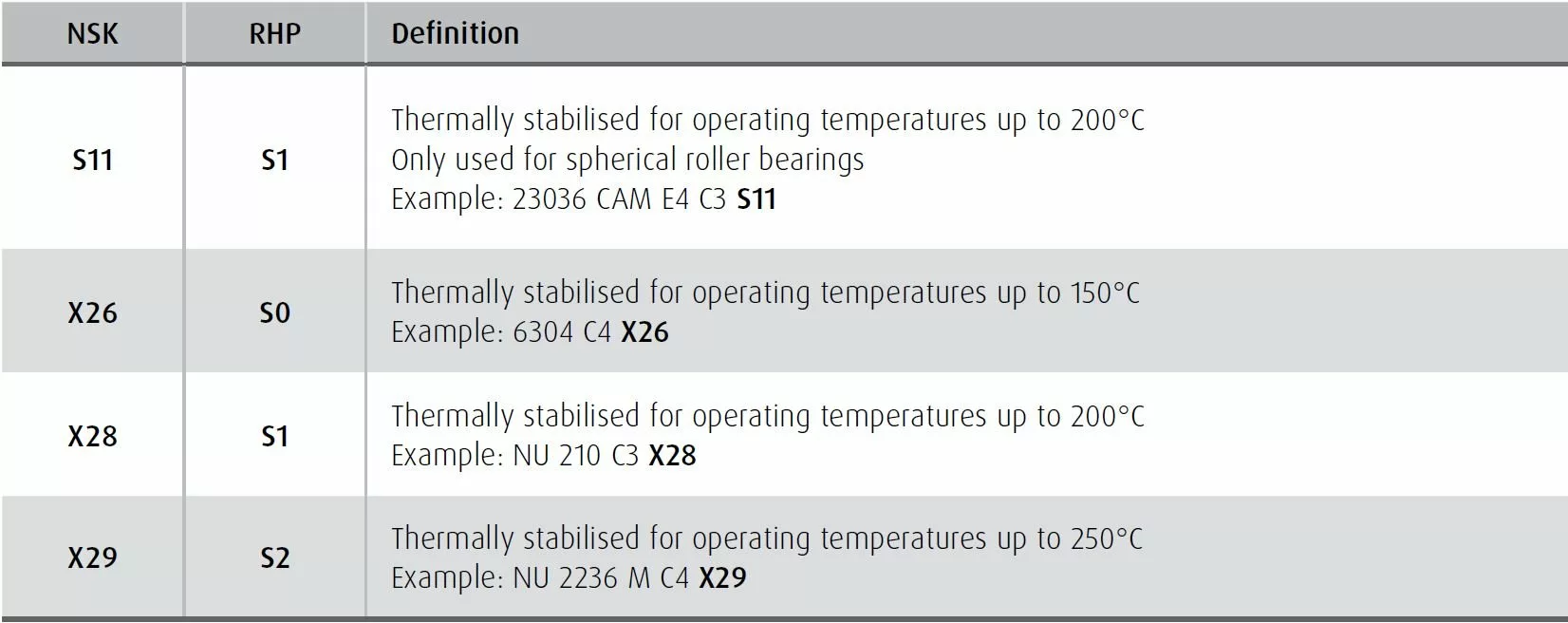

Table 3.10 – Heat treatment

Normal heat stabilisation for operating temperatures of up to 120°C is not marked on the bearing or the packaging.

Table 3.11 – Lubricants

Deep-groove ball bearings with seals or shields on both sides are supplied with a grease charge. The type and amount of grease varies depending on the operating conditions and bearing series.

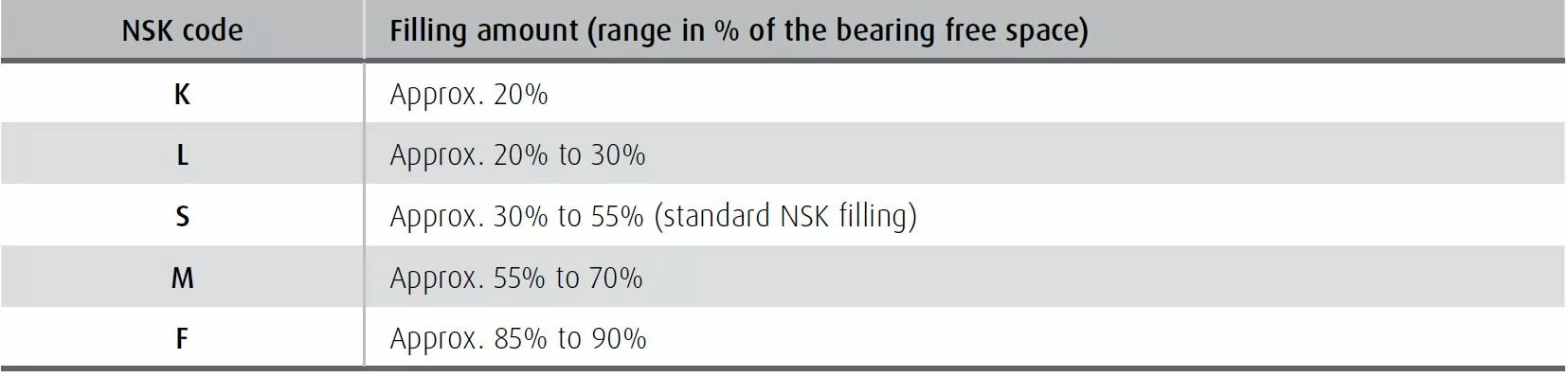

Table 3.11.1 – Common bearing greases

Table 3.11.2 – Amount of grease

The details provided here are mean values, which depend on the size and structure of the bearing (open, sealed on one side or sealed on both sides). The amount of grease used depends on the specific operating conditions. The codes for the type and amount of grease are written together at the end of the bearing designation.

Example: 6203 DDU C3E AS2S

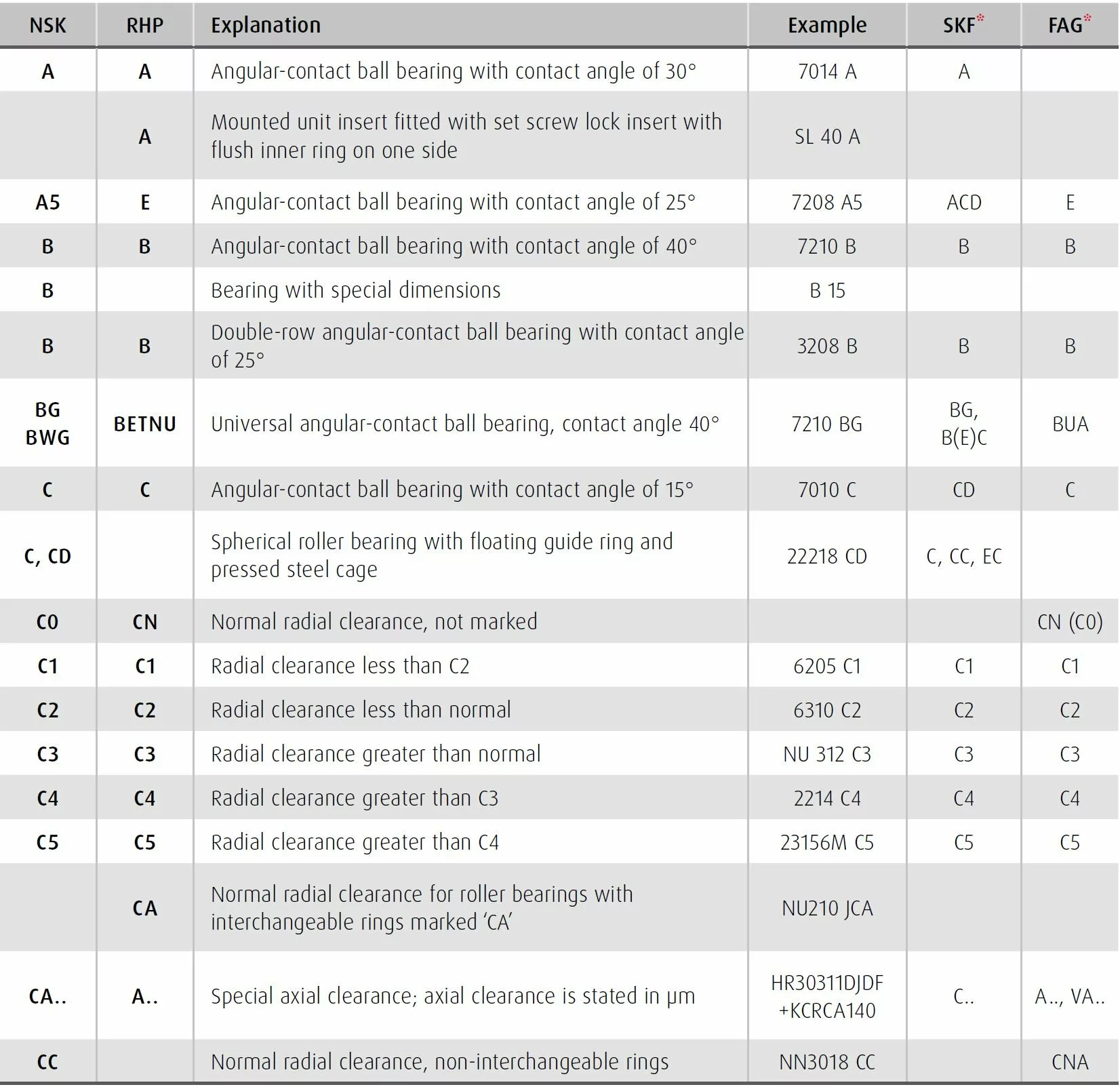

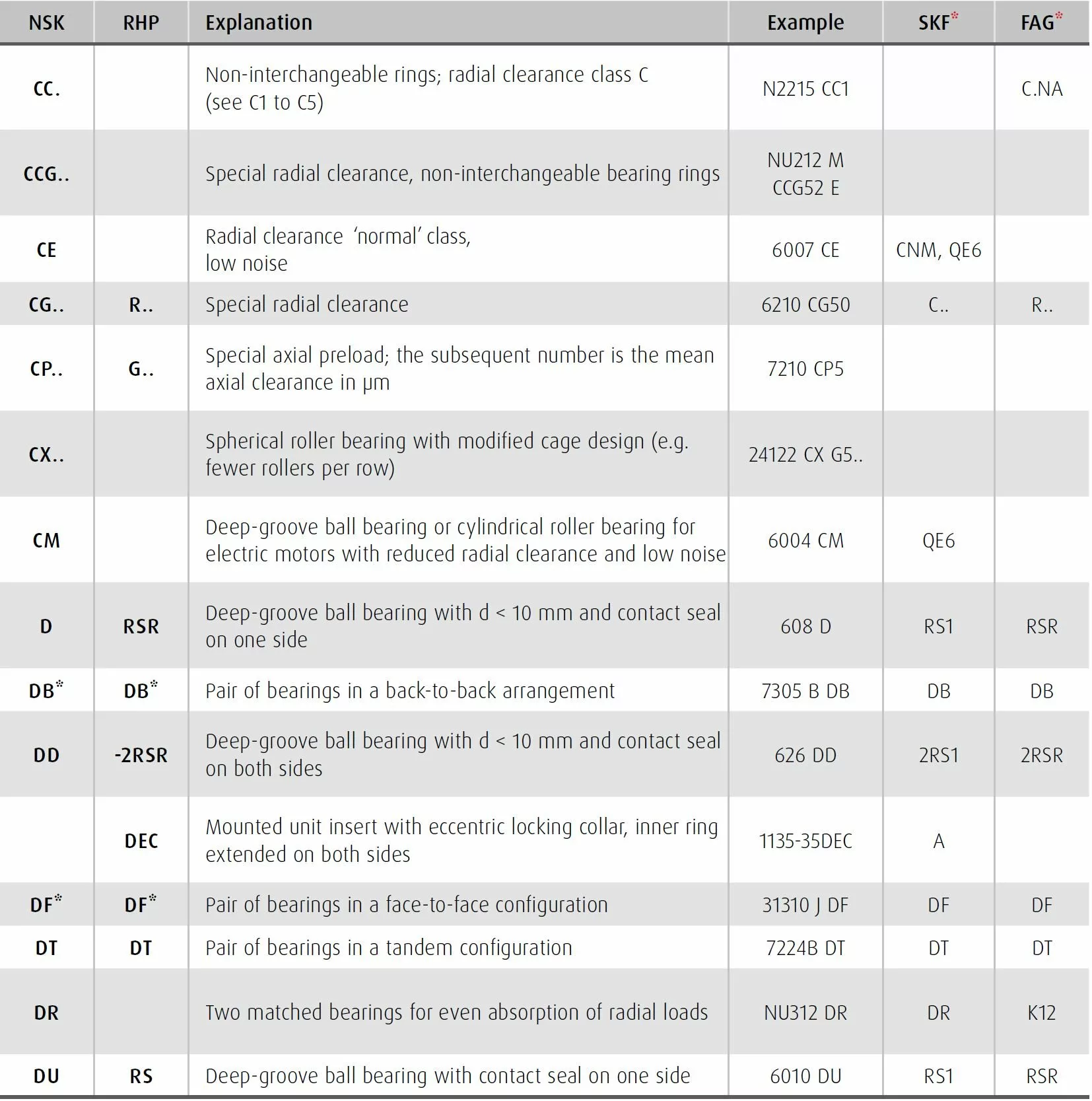

4 Suffixes: Comparsion of codes

Table 4

The bulk of this guide was taken from a supplement published by NSK bearings, hence a large amount of reference to NSK bearings.

I hope this helps and should you need any assistance in sourcing bearings or just figuring out exactly what bearings you need, just get in touch!