Precision engineering has been around for decades, and its importance to societal infrastructure has never been greater. Precision engineering has evolved over time to become a much more efficient form of creating products. Instead of having one person do everything on a project (like designing and creating), designers and engineers work together with automation software to create projects more quickly and efficiently than ever before. This new wave of innovation also allows us to produce products at an affordable price while also providing better customer service due to shorter lead times.

The new wave of innovation and intelligent automation has led to a shift in the way we work.

The way we manufacture products has changed, the way we do business has changed, and the way we live our lives has changed. In fact, it can be argued that the way we think about things is changing as well.

The fact that these changes are happening now should not surprise us; after all, they’ve been happening for hundreds of years! However what seems different today is how quickly these changes are happening (as opposed to decades ago) and how much more advanced they have become due both to technological advancements as well as social factors such as globalization which brings together people from all over the world who share new ideas and information faster than ever before.

In terms of engineering, it has been extremely beneficial because it has made it possible for companies to monitor their manufacturing processes and create products that are more affordable on both large and small scales. This is important because the world is becoming more dependent on new technologies, so we need to be able to produce goods efficiently in order to keep up with demand.

The most notable example of this is 3D printing. Using a 3D printer allows you to create any type of object that your imagination can imagine or model using software like SolidWorks or AutoCAD. The only limitation is the size and material of your printer; however, there are many different types available that allow you to print just about anything from jewelry pieces to plastic toys (or even human organs).

Robots make everything more scalable

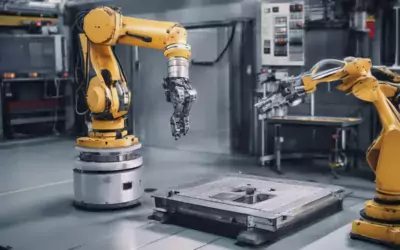

One of the reasons why robots are so popular is that they can do an enormous amount of work that would take many people days, even weeks, to complete. Robots can work faster and more efficiently than people.

Robots can perform tasks 24 hours a day, seven days a week, 365 days per year (as long as they have power). This makes them ideal for industries like manufacturing where demand for goods does not fluctuate during seasons or holidays. For example:

-

A company may want to produce 40 million washers per year but only needs to produce 300 washers each day during the peak season from June 1 through September 30 and only 250 washers each day between October 1st through May 31st. If manual labor were used then there would be too much staff working during non-peak times while not enough staff during peak times. With automation this problem goes away because robot’s don’t get tired like humans do. Another advantage is that robots never complain about how hot or cold it is or whether it’s raining outside or snowing. They also don’t take sick days or moan when the overtime gets cut!

There are a number of reasons why automation has become so popular in precision engineering today.

In the past, there were several reasons why automation was not a popular option for precision engineering. The first is that robots were very expensive to purchase and program. In addition to this, they required a lot of space and maintenance. Because these machines were so expensive and difficult to operate, it made more sense for companies to hire humans instead.

However, there has been an increase in interest surrounding precision engineering because of new technology advancements that have made robots much more cost effective:

-

Robots can do a lot of work in a short amount of time.

-

Robots are more precise than people (even if they’re programmed incorrectly).

-

Robots can be programmed to do things that people cannot (such as working in hazardous environments).

One reason is because it’s more effective at monitoring complex processes and situations than people, who may make mistakes due to human error. This is especially true when the process being monitored is an industrial one requiring a high degree of precision and accuracy. Robots are programmed to do a specific task, which means they can perform their duties with pinpoint accuracy that humans simply cannot match. They also don’t get tired or distracted like people do, so they can work for longer periods of time without getting fatigued or frustrated.

In addition to being able to monitor processes consistently better than humans can, robots are also able to handle tasks that would be too dangerous for human workers (such as working in areas with high levels of radiation) or difficult for them to complete (such as deep-sea diving). The fact that they don’t need rest makes them invaluable tools in any workplace where there needs monitoring done around the clock 24 hours per day 7 days per week 365 days per year!

In some cases, the use of a robotic arm is simply better able to handle the job than people because of the risk factors involved.

For example, robots can be used in situations where humans are at risk: In manufacturing plants, assembly lines often contain dangerous equipment and machines that could crush or cut fingers off if not handled correctly (or even accidentally). Robots can perform tasks that are too dangerous for people to do. They’re also programmed with strict safety protocols to ensure they don’t cause harm while working on their own; if anything seems amiss with the machine’s functioning or environment, it will stop work until either its programmer fixes the problem manually or someone else arrives who can help out with repairs. This means fewer accidents and injuries over time—which reduces costs associated with medical attention and insurance premiums!

When it comes to preventing injury from occurring in manufacturing plants, robots can be used to automate the process and allow for fewer workers on site during the day. They are safer than people and more accurate than people. Robots also work longer hours than people.

Engineering has evolved over time and will continue to evolve with technology.

One of the most interesting aspects of engineering is that it has evolved over time and will continue to evolve with technology. Over time, engineers have developed new products and services for consumers. This has led to new jobs and employment opportunities for people throughout the world.

The future of precision engineering is looking bright. As technology continues to advance and become more sophisticated, so does the industry of precision engineering. It’s important for engineers to stay up-to-date with these changes so that they can continue providing valuable services for companies in need of their expertise