Fanuc is one of the world’s leading manufacturers of robotics and industrial control systems.

It was founded in 1947 as Fuji National Corp., a semiconductor company, and sold its semiconductor operations in 1965 after which it began producing control systems for machine tools.

In 1972, Fanuc became its own company and changed its name to Fanuc Ltd. Shortly thereafter, they launched their first robot line and servo drive systems while introducing several other computerized machine tools including the S2M/S4M series which were smaller versions of their B series machines.

By 1979, Fanuc had introduced its first five axis robot arms with position and force feedback for applications like welding and machining. In 1986, a new series of CNC control boards were introduced called the “C” series including the C-1 through C-20 systems using a unique parallel bus architecture known as C-BUS (which is still used today).

By 1987 Fanuc had become the world’s largest manufacturer of industrial robots with over 20% market share (still true today) as well as an annual production capacity of 20 thousand units worldwide!

Fanuc was established in 1947 as Fuji National Corp.

Fanuc was established in 1947 as Fuji National Corp., a semiconductor company, to produce silicon semiconductors.

Fuji National Corp was the first company to mass produce silicon transistors in Japan; they were used primarily for television sets and radios at first but later made their way into computers as well.

In 1965, Fuji National Corp. sold its semiconductor operations, and started selling control systems for machine tools.

Fanuc’s first CNC machine was the FANUC B-2000, introduced in 1968.

Fanuc’s first CNC machine was the FANUC B-2000, introduced in 1968. The B-2000 was a 5-axis machine with a working envelope of 5′ x 8′. It was programmable from the front panel and could run at speeds up to 2000 rpm for milling operations, or 3100 rpm for drilling operations.

The B-2000 was the first CNC machine tool that didn’t use punch cards. It was a computerized machine tool, and used a proprietary language called FANUC 4D.

It was revolutionary because it allowed users with little knowledge of programming languages to create programs for their machines.

FANUC 4D allowed users to program directly from their computers . The B-2000 used this language and it became the standard for all future Fanuc control systems.

Fanuc introduced several other computerized machine tools in the 1970s

In the 1970s, Fanuc introduced several other computerized machine tools in the S2M and S4M series, which were smaller versions of their B series machines. The S2M was a small milling machine with a worktable measuring 7 inches by 11 inches (178 mm x 279 mm). It had four axes of rotation and could be used for any number of tasks including engraving or drilling holes in metal parts. The S4M was similar to its larger counterpart but with an even smaller work area: 4 inches x 6 inches (102 mm x 152 mm).

The smallest CNC control system ever produced by Fanuc was called “FANUC MACHINE CONTROL SYSTEM” or FMS-1A/B for short; it consisted only two axes (X-Y) controlled by one CPU card (CPU1) with 16K words memory space plus one more axis which may be added later on if needed so no additional cards were required at all! These systems were used widely during 1980s until early 1990s when PCs became affordable enough for home use making them obsolete today except maybe museum pieces…

In 1972, the name was changed to Fanuc Ltd.

Fanuc Ltd. was established in 1972 as a publicly traded company and the holding company for all of Fanuc’s business units. It was also at this time that they began to diversify their products beyond CNC controls and into other areas of automation such as robotics and mechatronics (the combination of mechanical devices with electronics).

Fanuc 6 Series

Fanuc released its first servo drive systems in 1979, which revolutionized their company and allowed them to compete with competitors such as Siemens AG.

In 1979, FANUC released the System 6 CNC series of controls, which had bubble memory technology. This new technology was an improvement over previous types of memory but had slow access speeds and was problematic. The company improved upon this technology by creating Large Scale Integrated chips (LSI), which significantly reduced the number of ICs in its products and increased reliability.

FANUC also introduced Pulse Width Modulation (PWM) drives that used transistors instead of SCR’s. This allowed for faster positioning speeds, because transistors are faster than SCRs.

Fanuc 7 Series

At about the same time that the 6 series was introduced, FANUC partnered with Siemens to create a more powerful control: the 7 series.

The 7 series came in a hardware version from Siemens and a hardware version from FANUC. FANUC built a separate team to engineer this control; years later, this team would also engineer FANUC’s 12 and 15 series controls while the team that designed the 6 series would also design the 10/11 and 16/18/21 series.

Thus began FANUC’s 2-team approach to building controls.

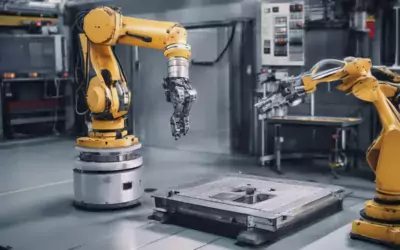

In 1982, Fanuc introduced its first five axis robot arms

In 1982, Fanuc introduced its first five axis robot arms with position and force feedback for applications like welding and machining. These robots were used in the manufacturing of cars and airplanes, as well as other industries such as shipbuilding and aerospace. Fanuc also designed these robots so that they could be easily integrated into existing systems using standardized connections between the robot controller and machine control system.

This made it possible for other manufacturers to build on this technology by creating their own customized solutions using Fanuc’s core components such as controllers or servo drives.

Fanuc are pioneers of innovation in their field

Fanuc is an innovative company with a long history of producing cutting edge products for industrial applications. The company was established in 1947 as Fuji National Corp., a semiconductor company, to produce silicon semiconductors. In 1965, Fuji National Corp. sold its semiconductor operations, and started selling control systems for machine tools. In 1970 they changed their name to Fanuc Ltd., which stands for “F”unctional Automatic Numeric Control (computer).

The popularity of these systems grew quickly due to their high performance and reliability compared to other types of control systems available at that time such as pneumatic or hydraulic systems; plus there were no moving parts within the CNC controller itself so there was less wear over time than with other types of controls which could result in lower maintenance costs over time!

In 1986, a new series of CNC control boards were introduced

In 1986, a new series of CNC control boards were introduced called the “C” series, including the C-1 through C-20 systems. These systems used a unique parallel bus architecture known as C-BUS.

The first system in this family was the C-1 which could handle up to 20 axes and used an 8 bit microprocessor with 2KB of RAM and 4KB of ROM. It also had a built in Ethernet connection that allowed it to communicate with other machines on your network or even other networks (if you had them).

This was followed later by:

- The C10 (which added more I/O options)

- The CM10 (which added more I/O options)

By 1987, Fanuc had become the world’s largest manufacturer of industrial robots

Fanuc was a pioneer in industrial robotics, and by 1987 it had become the world’s largest manufacturer of industrial robots with over 20% market share. Fanuc has an annual production capacity of 20,000 units worldwide.

Fanuc is one of the largest manufacturers of industrial robots in the world. They have an excellent reputation for quality and reliability, which has made them a leader in this industry since their founding in 1947.

Fanuc offers a wide range of products for various applications including automation systems, robotics and control systems – all designed with one goal in mind: improving productivity while lowering costs for customers around the globe.